Peter Kwasny GmbH is a medium-sized family company that has been developing innovative and patented solutions for paint aerosol systems and producing paint sprays, touch-up pencils and preparation products for a wide range of requirements and markets for over 60 years.

The brands of the Peter Kwasny GmbH

Kwasny's high-quality products are used in a wide range of application fields, for instance in the hobby sector, and by trade and craft professionals and painting specialists. We started off with Auto-K, the practical do-it-yourself solution for simple and fast paint repairs on cars. Today, our product range is popular among both professional users, professionals in painting booths (SprayMax) and also do-it-yourself users, or designers who use the products to decorate homes or in the hobby field. Today, Kwasny has become an international specialist for spray paint systems. The reputation we enjoy among our customers for the quality of our brands is motivation to continuously improve our products.

Let’s talk about advanced solutions to meet your specific needs.

Aerosol - Steel Cans

We've been a major supplier of aerosol steel cans for decades, putting all our experience, knowledge and technology into creating trusted, safe, delivery systems for products packed as aerosols. We produce millions of aerosols every year for major brands in the personal care, household, dairy and industrial sectors.

Aerosol - Aluminium Cans

Our aluminium cans offer all the major benefits of steel cans with the key added advantage of shaping options. We're able to produce quite complex shapes to aid marketing appeal and differentiation for our customers' products. Trusted, safe, precise packaging for personal care and toiletry products and home care items.

The British Aerosol Manufacturers’ Association has announced the winners of the BAMA Awards 2025. Sponsored by Sonoco, the awards ceremony took place on Wednesday 15th October at a new venue, the East Midlands Conference Centre in Nottingham. BAMA Chief Executive, Patrick Heskins commented: “We had an unprecedented number of entries this year which elevated the standard and presented the judges with a challenging task in deciding the winners in all categories.”

READ more

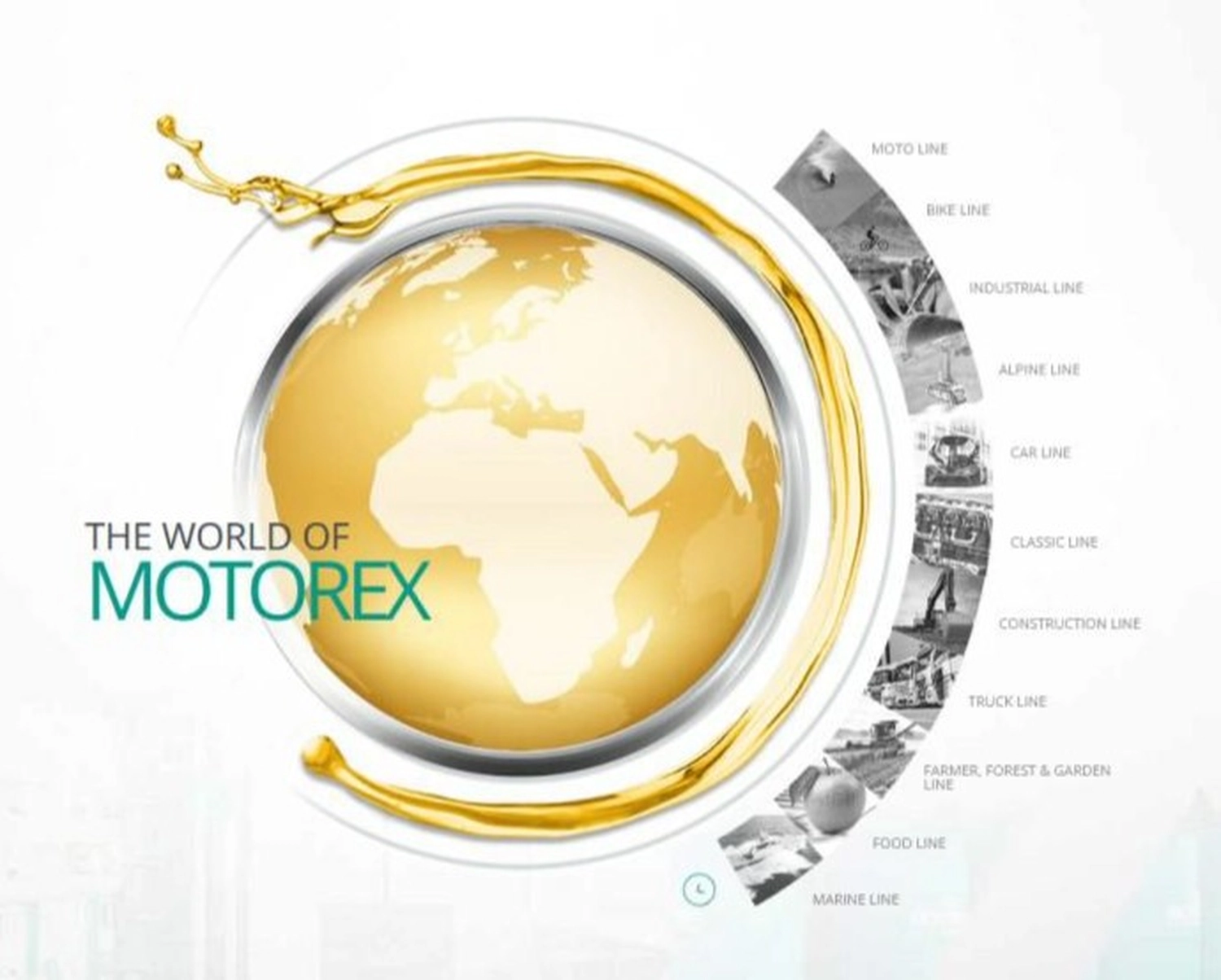

The 58th Annual General Meeting of the Swiss Aerosol Association (ASA) was once again a very special event, as confirmed by the large number of participants who attended. This year, the members once again began with a tour of the MOTOREX company in Langenthal. As early as 1917, pioneer Arnold Bucher began manufacturing REX leather and floor care products in Bützberg near Langenthal. With increasing motorization, the business shifted its focus, and REX became MOTOREX in 1947. MOTOREX-BUCHER GROUP AG remains an independent family business. The diverse product range is enormous. There are more than 40 different spray products alone.

READ moreWe offer quality valve products at competitive prices.

Since its founding in 1991, 7M Valf has supplied aerosol valves, actuators, spray pumps and their components to the world's leading production and manufacturing sectors.

Due to our long-lasting partnership with Aptar Holding, a driving force in the global spray systems market, we have successfully provided our customers with high procurement opportunities and competitive prices.

The British Aerosol Manufacturers’ Association has reported 2024 as a solid year for the UK aerosol dispensing filling sector with an increase of almost 2% over 2023, showing a return to growth following a few flat years. This year, the trade association has also released personal care and household aerosol retail sales figures supplied by Kantar World Panel.

Personal care maintains growth

The standout sector which makes up 75% of the total market is personal care with an overall increase of 3% from 2023. With a 2.9% growth in deodorants, a 5% increase in antiperspirants and tanning and suncare rising by 22.5%, growth is evident across a number of categories. For the first time in recent years, shaving preparations have also grown, indicating a possible turning of the tide for the category.

Household products fall

In contrast, household product numbers have slowed compared to 2023, reinforced by a drop in the filling of air fresheners, as other formats for dispensing fragrance in the home continue to grow, and, as more of the furniture consumers have in the home is produced from manmade materials, furniture polish filling has also been impacted.

BAMA Chief Executive, Patrick Heskins says: “We’re delighted to see overall growth, especially as market challenges persist. Part of the drop in Household Products can be accounted for by the growth in number of Industrial Aerosols filled as the numbers for DIY lubricants appears to have been reported in this section for 2024. This is probably also true as to why the number of Paints and Lacquers shows a reduction as these have been picked up under Automotive.”

Impressive growth in smaller categories

Some of the smaller categories showed significant growth, with medical aerosol products up by over 5% and insecticides by nearly 27%. Also, the number of oven cleaners filled more than doubled, and, the miscellaneous category, which includes products such as glitter sprays and temporary hair colours, showed phenomenal growth.

The share of the market for aluminium and tinplate continued to go in favour of aluminium, with the split now 32% for tinplate and 68% for aluminium compared to a 38:62 split in 2023.

Aerosols remain firm export product

The numbers, which are supplied by UK fillers, indicate that aerosol dispensers continue to be a strong export product, with nearly 70% of the products made in the UK going to the EU (approximately 50% of production), and elsewhere in the world.

Patrick adds: “Thank you to all those who contributed to our survey this year. The strong response means we can be confident that the numbers shown are accurate and reflect the continued success of our industry in a tough global market.”

UK Aerosol Sales Insights

In addition to filling data, BAMA has also released aerosol sales figures supplied by Kantar World Panel. The numbers represent retail sales of aerosol products within the personal care and household sectors, purchased in the UK between 2015 and 2024.

With a drop in body spray purchases, the data reveals signs of a ‘trade up’ to deodorants as a larger variety of antiperspirants have become more readily available to consumers since 2015. Mirroring increased filling figures, suncare products also rose from 1,342 units in 2015 to 5,322 units in 2024. The ongoing decline in haircare aerosol sales may reflect shifts in fashion which, unlike other decades have not necessitated more styling products for women’s hair.

Patrick says: “The last decade has encountered numerous global and political developments, some of which are reflected in the sales figures. Our aim with the data is to provide as accurate a picture as possible for all industry stakeholders. Overall, the aerosol format has continued to perform and remained resilient to a host of challenges over the last 10 years, helping it to stand in good stead for the future.”

Coster Group is proud to announce the opening of its new production facility in Cabreúva, São Paulo, Brazil. This strategic expansion further strengthens the Group’s presence in South America and supports its continued growth in the region.

The new plant, operational since June 2024, marks a significant step in Coster Group's strategy to expand its global operations. With the ability to manufacture aerosol valves, actuators, and pumps, the Cabreúva site is set to increase the capabilities of the Group in Brazil and South America, working together with the historic site in Pilar (BsAS), Argentina.

Coster Group has invested over US$ 15 million in the Cabreúva plant, which was built and made operational in a record time of under 12 months. Covering a total area of 18,000 m2, the facility features 5,000 m2 of built-up area and 3,000 m2 of expansion space. The new plant is equipped with the latest technology to maximize efficiency and enhance product quality, permitting the company to meet growing demand in the strategic and growing Brazilian market. Clients will benefit from increased production capacity, a broader product portfolio, shorter lead times, and a reliable local supply. In addition to aerosol valves and actuators, the site will serve as a hub for perfumery pumps, offering a new alternative to the local market.

“We are extremely proud of the rapid development of our Cabreúva plant,” said Bernard Msellati, CEO & President of Coster Group. “This facility is a central part of our strategy to strengthen our regional operations, supporting our growing Brazilian customer base in both aerosols and perfumery. A special thanks to our team and all our partners who contributed to making this project a success.”

On December 31, 2024, the California Department of Resources Recycling and Recovery (CalRecycle) released several reports pursuant to SB 343, California’s Truth in Labeling for Recyclables law, and SB 54, the state’s packaging Extended Producer Responsibility (EPR) law, as required by deadlines in both laws.

CalRecycle first released the annual update to the list of covered materials under SB 54. This publication provides an update to recyclability and compostability determinations for covered material categories (CMC). Importantly, CalRecycle updated the list to explicitly note both steel and aluminum aerosols as recyclable, along with steel packaging in general, which HCPA strongly advocated for.

Also for SB 54, CalRecycle published its estimate of the baseline for the 25-percent source reduction requirement for covered single-use plastic material under the law. The report establishes the source reduction baseline for the weight of plastic and number of plastic components associated with single-use plastic packaging and single-use plastic food service ware sold, offered for sale, or distributed in the state in the 2023 calendar year.

On December 31, 2024, the California Department of Resources Recycling and Recovery (CalRecycle) released several reports pursuant to SB 343, California’s Truth in Labeling for Recyclables law, and SB 54, the state’s packaging Extended Producer Responsibility (EPR) law, as required by deadlines in both laws.

CalRecycle first released the annual update to the list of covered materials under SB 54. This publication provides an update to recyclability and compostability determinations for covered material categories (CMC). Importantly, CalRecycle updated the list to explicitly note both steel and aluminum aerosols as recyclable, along with steel packaging in general, which HCPA strongly advocated for.

Also for SB 54, CalRecycle published its estimate of the baseline for the 25-percent source reduction requirement for covered single-use plastic material under the law. The report establishes the source reduction baseline for the weight of plastic and number of plastic components associated with single-use plastic packaging and single-use plastic food service ware sold, offered for sale, or distributed in the state in the 2023 calendar year.

CalRecycle published the SB 343 Material Characterization Study (MCS) Revised Preliminary Findings Report, the required characterization study of material types and forms that routinely become feedstock used in the production of new products and packaging. This report is an update to the initial preliminary findings report published on December 28, 2023, and includes refined analyses, additional data tables, and other changes based on additional data collection and in response to public comments. The updated report found that steel and aluminum aerosols meet the collection and sortation thresholds for recyclability in the law, as does steel packaging in general, which HCPA strongly advocated for.

The SB 343 MCS Revised Preliminary Findings Report still does not provide on whether material types and forms meet the additional criteria in the law that the sorted recyclables be sent to and reclaimed at a reclaiming facility consistent with the requirements of the Basel Convention, or on materials collected via drop-off programs. As such, unlike the SB 54 CMC list, this report does not include determinations by CalRecycle of which material types and forms satisfy the requirements of SB 343 to carry a “recyclable” claim. If a material meets the collection and sorting criteria, it may be eligible to be labeled as recyclable, but it will need to also meet additional criteria in the law not addressed in this report in order to carry the claim.

CalRecycle will host a formal public meeting to present the revised SB 343 preliminary findings and allow interested parties to provide comments on February 3, 2025 at 9:00 am – 12:00 pm PT, with options to attend virtually via Zoom and in-person in Sacramento. HCPA will be in attendance and anticipates that this meeting will trigger the continuation of the legal timeline for SB 343 implementation. As such, the compliance date is estimated to be in the range of September 4 – October 4, 2026 (the law would apply to all products manufactured after this date).

An HCPA Webinar

Industry Training:

How to Determine the MIR of an Ingredient

February 13 | 1:00 - 2:00 pm ET

The California Air Resources Board (CARB) recently launched the next Consumer and Commercial Products Survey, which aims to gather data to inform future standards. While previous surveys have focused on volatile organic compounds (VOCs), this survey is focused on Ozone Forming Potential (OFP). CARB has been addressing their regulatory definition of VOCs through mass-based VOC standards, which excludes exempt compounds and low vapor pressure (LVP) VOCs. Industry relies on those exempt VOCs and LVP-VOCs for many product categories, which has resulted in questions around the feasibility of future mass-based VOC standards.

CARB must continue addressing the state’s nonattainment status with the National Ambient Air Quality Standards (NAAQS) for ozone, thus they are looking to shift from the mass-based VOC approach for consumer products to photochemical reactivity through Maximum Incremental Reactivity (MIR).

In this webinar, Nicholas Georges, Senior Vice President, Scientific & International Affairs, HCPA, and Doug Raymond, industry consultant, will educate attendees about this regulatory change and how to determine the MIR of the ingredients used to formulate products.

CARB Hosts Workshop on Toxicity Ranking Methodology

On January 16, the California Air Resources Board (CARB) conducted a workshop with stakeholders to provide further detail on the toxicity ranking methodology used for the 2023 Consumer and Commercial Products Survey. Per CARB’s methodology, 17 product categories in the survey have been targeted for potential inclusion of parachlorobenzotrifluoride (PCBTF).

Depending on the results of the survey and an alternatives analysis, PCBTF may be restricted in certain product categories in the next CARB rulemaking. HCPA is currently hosting meetings for members to discuss the survey and provide additional details of the upcoming rulemaking.

HCPA Meets with Colorado RAQC on Consumer Products

On January 22, HCPA met with the Colorado Regional Air Quality Council (RAQC) to discuss volatile organic compound (VOC) regulations.

In recent years, HCPA has participated and supported rulemaking processes in Colorado that adopted VOC standards based on the Ozone Transport Commission’s (OTC) Phase IV Model Rule for Consumer Products, as well as a contingency measure that would update the rule to align with the OTC Phase V Model Rule should it be necessary based on the nonattainment status in the Denver metro area with respect to the National Ambient Air Quality Standard (NAAQS) for Ozone at 75 ppb.

The RAQC is exploring potential measures to compliance with the 70 ppb Ozone NAAQS and considering further activity for consumer products, including potentially turning the contingency measure into a mandatory requirement for industry sooner.

HCPA will continue to participate in RAQC meetings in February and March.

Regulatory Freeze and Updated HCPA Regulatory Tracker

One of the first actions of the new Administration was to issue an executive order that freezes all regulatory activity for 60 days to perform a review and determine how to proceed on certain actions. On January 17, before President Biden left office, he updated the Regulatory Agenda to reflect estimates for ongoing regulatory activity. Many of these actions, priorities and timelines will now likely shift.

The HCPA Regulatory Tracker is operational on the HCPA member site or using this link. The Regulatory Tracker is designed to provide members with an overview of relevant regulatory activity, including 25(b) Registration, Aerosol Universal Waste, Extended Producer Responsibility (EPR), Neonicotinoids, PFAS, and VOCs. The information will be updated regularly and is meant to complement meetings and email communications. HCPA will host a webinar to walk members through the platform and answer questions.

Global aerosol dispensing leaders, the LINDAL Group has launched FlipStraw – a dual spray actuator with foldable straw designed for homecare and technical applications.

Offering a more streamlined assembly, lightweight design and numerous spray options, FlipStraw has already attracted a surge of enquiries following its official launch at the Aerosol Dispensers Forum in Paris last month. Gabriele Marchetti, LINDAL Italy’s Head of Sales says: “We have been delighted to receive such positive feedback since FlipStraw was showcased at ADF. I think customers appreciate both the manufacturing and product-specific benefits, and also welcome a new alternative that is locally produced in Europe.”

One of FlipStraw’s key advantages is its ease of assembly to a can. Since no pre-heating or special tools are required, the manual fitting process becomes significantly more time-efficient. The weight of the actuator is significantly lighter than similar products too, and, because it is compatible with a range of LINDAL inserts, there is a wide variety of spray pattern options available if required.

Compatibility and design features

FlipStraw is compatible with LINDAL’s male valves (LI) and one-inch (LIB) ball valves making it suitable for a broad variety of applications, including inverted orientation applications. There are also two different straw lengths available as standard to accommodate different can sizes.

The smart design behind FlipStraw makes it top load resistant, preventing actuation of spray during stacking and transportation. Also, to help ensure the integrity of the pack, a moulded one-time use tearaway tap is integrated into the design.

Tailored branding is possible with a finger pad that is available in red, translucent and black, with more colour options available soon. Furthermore, to help optimize packing efficiency, FlipStraw is packaged with the straw folded.

Gabriele adds: “Based on the level of orders and enquiries we have received so far, we would encourage customers and others who are interested in FlipStraw, to please contact us soon.”

Aluminium Deutschland (AD) is pleased to announce the election of Johannes Schick, CEO of the Linhardt Group, as the new Chairman of its Tubes, Cans, and Impact Extruded Parts Division. Schick assumed the role at the beginning of 2025 and will serve a two-year term.

He succeeds Clemens Behrenbruch, Managing Director of Alltub Germany, who has led the division with dedication and expertise. Under the leadership of Mr. Behrenbruch, the division has navigated key industry developments and strengthened its position within the aluminum packaging sector.

"I am honored to take on the role of Chairman at such a crucial time for our industry," said Johannes Schick. "With ongoing challenges and opportunities in sustainability, innovation, and regulatory developments, I look forward to working closely with our members to drive progress and advocate for the interests of our sector."

Clemens Behrenbruch reflected on his tenure, stating, "It has been a privilege to serve as Chairman of this division. I am confident that Johannes Schick will continue to advance our industry’s priorities, and I wish him every success in his new role."

Aluminium Deutschland extends its sincere gratitude to Clemens Behrenbruch for his valuable contributions and leadership. With Johannes Schick at the helm, the division is well-positioned to address future industry challenges and strengthen the role of aluminum packaging in Germany.

Significant recovery in the second half not enough to turn the year around

Düsseldorf, 12 February 2025

After a challenging first half of 2024, members of the Tubes, Cans, and Impact Extruded Parts Division of Aluminium Deutschland reported a notable shift in the German market for aluminum tubes and aerosol cans in the second half of the year, as deliveries to Germany showed signs of recovery.

Aluminium Aerosol Cans – Recovery in Second Semester

In contrast to the 10.3% decline in the first half of 2024 compared to the same period in 2023, the aerosol cans market experienced a 7% increase in the second half (compared to H2 2023), with a total of 285 million cans delivered to Germany. Demand seems to be recovering after the significant drop in the first half. Despite this recovery, 2024 marked an overall decline in deliveries to the national market, with a total of 562.5 million cans delivered, reflecting a 2.3% decline compared to the previous year.

Aluminum Tubes – Decline Continues, but Rate Improves

While the aerosol can segment showed significant growth in the second half, the aluminum tubes sector faced a slight decline of 0.6% in H2 2024 compared to the same period in 2023. This represents a notable improvement from the 6.4% drop observed in the first half of the year, signaling a deceleration in the rate of decline. Overall, approximately 767 million tubes were delivered to the German market in 2024, marking a 3.7% decline compared to the previous year.

Yearly Overview and Outlook for 2025

Despite the declines, the industry demonstrated resilience, with the second-half recovery bringing optimism for the future. Chairman Johannes Schick of the Tubes, Cans, and Impact Extruded Parts Division of Aluminium Deutschland remarked, “The stable production volumes reported by our member companies are a clear indication of the industry’s adaptability. While domestic deliveries have faced challenges, growing demand from other regions has helped offset the decline in the German market.”

The drop in deliveries to Germany reflects a shift in production and filling capacities abroad, reducing demand from local facilities. Looking ahead to 2025, the industry remains cautiously optimistic. While challenges such as the skilled labor shortage and high energy costs persist, Schick emphasized, “Proactive innovation, market adaptability, and supportive policies will be crucial to maintaining our competitiveness as we navigate these ongoing hurdles.”

Looking Ahead: Political and Market Uncertainty Add Pressure

The uncertainty surrounding global trade policies, particularly in relation to U.S. President Donald Trump’s policies, and the current political instability in Germany continue to add complexity to the market landscape. The industry emphasizes the need for a stable and supportive regulatory environment to address these challenges.

______________________________________

Contact:

Seifeldin Raslan Mohamed

Aluminium Deutschland e. V. (AD)

T +49 211 4796-280

seifeldin.raslan@alu-d.de

Significant growth in production volumes, except in the home products segment

In 2024, the production of aerosol dispensers in France increased by almost 10% (657.91 million units in 2023 vs. 723 million units in 2024). This growth included the body care and “other” segments. The home care segment, on the other hand, is slightly down. This progress in production shows the dynamism of the French industry in a market where consumers are attracted to aerosol dispensers as a safe, easy-to-use, inexpensive and recycled form of packaging.

The 2024 activity of filling aerosol dispensers shows growth, a trend already seen last year. The French aerosol industry maintains its strong position in Europe (to be confirmed when FEA figures are published in September 2025).

Two growing segments:

The pharmacy and veterinary segment (+8%). The auto/cycle, paint and industrial & technical products segment returned to its 2022 level (+43%), while the food/other segment took off with the strongest growth (+62%).

One decreasing segment:

• Home care (-5%) is down, but the insecticides and horticultural products sub-segment is sharply up (+51%).

An increase of +4% for a total filling of 518 million units of aerosol generators in 2024, with this segment accounting for 72% of production.

Deo and antiperspirants: +3%

Slight growth in this segment, which is major in terms of application. The launch of new brands and the “easy to use” products may explain this phenomenon. Promotional activities may also have had an impact on demand. The segment accounts for 19% of French fillings.

Hair foams and lacquers: +0.5%

After declining in 2022, this segment grew strongly in 2023. It held steady in 2024, representing the largest segment of total sales in France, at 22%.

Shaving foams and gels: -2%

This segment made good progress in 2023. In 2024, it lost two points and still represents 8% of production in France.

Suncare products, watersprays, dry shampoos, others: +10%

This segment grew by 30% in 2022, fell by 4% in 2023, and its growth in 2024 brings it back to a level well above that of 2019. This category represents products that are highly versatile and quickly impacted by external phenomena such as fashion or weather. 2024 saw new brands launched, as well as new aerosol body care applications. The segment still represents a significant 23% of French production in 2024.

A drop of -5% for a total fill of 72 million aerosol dispenser units in 2024, representing 10% of total production.

Air fresheners: -9%

This segment had risen significantly in 2023. At the time, this increase was explained by promotional activities. In 2024, a readjustment seems to have taken place. The drop in production in this segment has not reduced its importance in relation to total production, since it still represents 5% of the latter.

Insecticides and horticultural products: +50%

As a reminder, in 2023, this segment suffered a 55% drop. The catch-up in 2024 is undoubtedly linked to production movements from abroad. The product is still popular with consumers, despite complex regulations. The meteorological aspect continues to have a major impact (mosquitoes, hornets, etc.). This segment, which represented 2% of total sales in 2023, gained one point in 2024.

Carpet/textile care, furniture care, oven cleaners, bathroom and kitchen cleaners, leather and shoe care and other household products: -88%

This decline is the biggest of all segments in 2024. It is the first decline in several years of growth. It may be explained by the relocation of these specific products, or by a drop in demand for kitchen and bathroom disinfectants. This segment fell from 4% of total production in 2023 to 2% in 2024.

A total volume of 133 million aerosol dispensers, up 36%, making up for a -35% drop in 2023. The segment recovers to 18% of total activity.

Auto & Bicycles / Paints & Varnishes / Industrial & Technical: +42%

This segment, which accounts for 13% of total sales, fell inexplicably by -43% in 2023 and 2024 brings it back in line with expectations. The need for these specific products remains constant, and the practical, efficient aerosol packaging contributes to their attractiveness.

Pharma / Veto (Excluding MDI): +8%

The growth of this segment, which will still account for 4% of total sales in 2024, is proof of France's mastery of the filling of complex products. Traditionally, France was the country where pharma was produced. This rapid growth is no exception.

Food and miscellaneous: +61 %

This segment, which had remained stable in 2022 and experienced a decline in 2023, is on the rise again. This is relative in terms of volume, but the percentage impact is significant. This segment now represents 1% of total production. The Statistics Committee welcomed the arrival of new products in France, such as cooking oil.

Production outlook 2025

Our view is that supply disruptions had repercussions in 2023, and that these were less severe in 2024.

But this year, raw material costs and inflation are still present and still impacting purchasing power. But as in 2024, not all segments will be impacted in the same way.

_____________________________________

BAMA announces details of Innovation Day 2025 program

The British Aerosol Manufacturers Association has announced details of its program for the BAMA Innovation Day 2025. This year, the event is sponsored by global aerosol dispensing specialists, LINDAL Group, and will take place on Wednesday 23rd April at the Royal Armouries Museum in Leeds.

LINDAL will open the program by sharing details of its ‘Turbo Valve’ designed to help increase market acceptance of compressed gas systems. Topics that follow will provide insights on the direction of the French aerosol industry, the safe filling and handling of CO2 as a propellant, AI and manufacturing, historic lessons on waste reduction and recycling, and creative thinking methodologies behind sustainable packaging.

There will also be presentations on zero-based packaging design, cardboard caps, spray re-fill stations, new can making technologies, and developments within quality and safety for aerosol production lines.

Level 2 training launch

Featuring on the day will be the launch of BAMA’s new Level 2 training modules. Following the successful launch of the association’s video training courses in 2022, BAMA will explain more on how members will benefit from a new series of multimedia training units covering Aerosol Dispenser Regulations, Flammability in the Aerosol Factory, the Transport of Aerosol Dispensers by Road, Rail, Air and Sea and the Labelling of Aerosols.

BAMA Chief Executive, Patrick Heskins says: “Aerosol innovation is happening all the time; across all areas within the industry and we thrilled to have another diverse and full programme that is testament to this. One of the key themes that stands out this year is understanding lessons of the past and creating new paths to secure the longevity of our industry’; tackling ongoing challenges with bold solutions and creative strategies.”

The full day event will be divided into four speaker sessions with exhibiting and networking taking place in between in the Exhibition Hall. A free to attend event for members and non-members – to book your place at the Innovation Day please visit: https://bama.co.uk/event/Innovation-day-2025

Precision Valve Corporation, a leading global manufacturer of aerosol valves, actuators, and other dispensing solutions, today announced the appointment of Thierry Bouan as Chief Executive Officer, effective immediately. Mr. Bouan succeeds Harald Biederbick, who has served as Chief Executive Officer since 2022. We thank Harald for his many contributions to Precision and we wish him the very best in his future endeavors.

Mr. Bouan joined Precision in 2017 and has been responsible for leading all aspects of the Asia Pacific business. Throughout his tenure, he has successfully driven operational and commercial value-creation initiatives, demonstrating strong leadership and a commitment to excellence. With extensive experience in business transformation, he is well-positioned to guide Precision’s continued growth and innovation.

Prior to joining Precision, Mr. Bouan spent a decade at Global Closure Systems, a leading global manufacturer and provider of closures and dispensing systems, where he ultimately led the company’s Asian operations, overseeing a P&L with 600 employees and managing three manufacturing sites across the region. Mr. Bouan also spent nine years at Crown Holdings, a designer and manufacturer of packaging solutions for consumer goods, where he served in a senior management role, overseeing 150 employees and leading operations across France, Spain and Italy.

“On behalf of the Board of Directors, we are thrilled to appoint Thierry to this new leadership role” said Ryan Mashinter, Senior Managing Director at ONCAP. “Thierry’s extensive experience and demonstrated track record of value creation through strong corporate strategy and business transformation initiatives bodes well for Precision going forward.” Mr. Mashinter continued, “We would also like to thank Harald for his leadership and many contributions to Precision. We wish him all the best in his future endeavors.”

Mr. Bouan commented “I am honored to take on this role and lead Precision at such a pivotal moment in its journey. With its deep-rooted history, strong reputation for innovation and quality, and expansive global footprint, Precision is well-positioned for the future. I am excited to work alongside our talented team to drive the next phase of expansion and deliver even greater value to our customers and stakeholders. The opportunities ahead are exciting and I look forward to building on the Company’s strong foundation to achieve new levels of success.”

Significant recovery in the second half not enough to turn the year around

After a challenging first half of 2024, members of the Tubes, Cans, and Impact Extruded Parts Division of Aluminium Deutschland reported a notable shift in the German market for aluminum tubes and aerosol cans in the second half of the year, as deliveries to Germany showed signs of recovery.

Aluminium Aerosol Cans – Recovery in Second Semester

In contrast to the 10.3% decline in the first half of 2024 compared to the same period in 2023, the aerosol cans market experienced a 7% increase in the second half (compared to H2 2023), with a total of 285 million cans delivered to Germany. Demand seems to be recovering after the significant drop in the first half. Despite this recovery, 2024 marked an overall decline in deliveries to the national market, with a total of 562.5 million cans delivered, reflecting a 2.3% decline compared to the previous year.

Aluminum Tubes – Decline Continues, but Rate Improves

While the aerosol can segment showed significant growth in the second half, the aluminum tubes sector faced a slight decline of 0.6% in H2 2024 compared to the same period in 2023. This represents a notable improvement from the 6.4% drop observed in the first half of the year, signaling a deceleration in the rate of decline. Overall, approximately 767 million tubes were delivered to the German market in 2024, marking a 3.7% decline compared to the previous year.

Yearly Overview and Outlook for 2025

Despite the declines, the industry demonstrated resilience, with the second-half recovery bringing optimism for the future. Chairman Johannes Schick of the Tubes, Cans, and Impact Extruded Parts Division of Aluminium Deutschland remarked, “The stable production volumes reported by our member companies are a clear indication of the industry’s adaptability. While domestic deliveries have faced challenges, growing demand from other regions has helped offset the decline in the German market.”

The drop in deliveries to Germany reflects a shift in production and filling capacities abroad, reducing demand from local facilities. Looking ahead to 2025, the industry remains cautiously optimistic. While challenges such as the skilled labor shortage and high energy costs persist, Schick emphasized, “Proactive innovation, market adaptability, and supportive policies will be crucial to maintaining our competitiveness as we navigate these ongoing hurdles.”

Looking Ahead: Political and Market Uncertainty Add Pressure

The uncertainty surrounding global trade policies, particularly in relation to U.S. President Donald Trump’s policies, and the current political instability in Germany continue to add complexity to the market landscape. The industry emphasizes the need for a stable and supportive regulatory environment to address these challenges.

TUBEX also received an ADF certificate together with PPG, for the joint development of an innovative internal coating especially for wine and wine-based drinks in aluminium bottles.

TUBEX is thrilled to have played a key role in DFNS’ success at the ADF Awards. TUBEX's knowledge and experience in aerosol can tooling has been instrumental in the production of the innovative adidas CARE by DFNS Footwear Protector aluminium aerosol can, which was recognized for its cutting-edge design and functionality. The aluminium can not only has a cutting-edge design – it is also powered by alu-air© and cuts emissions by 79 % compared to traditional aerosols. The adidas CARE aluminium can is an eyecatcher on the point of sale and testament that sustainability and design perfectly match.

This achievement further demonstrates TUBEX’s expertise in high-quality aluminium aerosol can manufacturing.

Receiving an ADF certificate as well for the collaborative development with PPG for an advanced internal lacquer solution, especially for wine and sparkling wine for aluminium bottles was the icing of the cake at the Award Ceremony.

Aluminium bottles are gaining traction due to their sustainability, durability, and premium aesthetics. In response to this trend, TUBEX’ partnership with PPG led to the rapid development of a high-performance internal lacquer, ensuring superior product protection, easy application, compatibility, and safety. The local proximity of the two companies was key to the development of the internal coating and enabled the TUBEX production and PPG lab team to work fast and well together – ensuring a smooth and efficient process.

On top of the superb properties the award-winning internal lacquer is BPA-ni and already meets the regulation of tomorrow.

This recognition underscores TUBEX commitment to innovation in the fast-growing aluminium bottle market.

TUBEX extends its sincere gratitude to their partners PPG and DFNS, for their collaboration and shared vision. Together, we are driving innovative developments in aluminium packaging and setting new industry benchmarks.

The British Aerosol Manufacturers’ Association has announced that Neil Bolton, Global Product Stewardship Director at Procter and Gamble has been appointed Vice-Chair of the BAMA Board of Directors.

With over 30 years’ experience working with Procter and Gamble in Research and Development, Regulation, Human Safety and Post-Market Safety Surveillance roles, Neil will be drawing on his extensive expertise to work with the Board on a diversity of industry initiatives and developments and to further support Association members.

Neil has remained active in the industry throughout his career, sitting on the BAMA Board of Directors since 2020 and as a member of its Regulatory Affairs committee in the 1990s. He has also been involved extensively with numerous industry bodies and regulators across Europe, Chairing and Co-chairing association committees at CTPA, PAGB, Cosmetics Europe and AESGP. Neil says: “Being involved with the work associations do is hugely rewarding, so, it’s a real pleasure to take on the role of Vice-Chair at BAMA and to play a part in building on the hard work that goes into making our industry successful. I look forward to joining forces with everyone on the Board and actively engaging with member companies across all industries.”

BAMA Chief Executive, Patrick Heskins adds: “Neil’s technical, business and organisational experience, along with his people development and management skills will bring invaluable benefits to the Board and to our members. We are delighted to welcome him as Vice-Chair.”

Colep Packaging is thrilled to announce that, as of 1 January 2025, ALM, SL will operate under the Colep Packaging brand, adopting its corporate identity, and being governed by the principles, culture and values that guide the Organization.

This milestone is the culmination of ALM’s integration process, whose entire share capital was acquired last July, in a strategic consolidation move for Colep Packaging. The process that has now been completed is more than an organizational change: it represents the merge of strengths, experience and talents of both teams, reinforcing the ability to deliver top quality products and solutions to the company’s customers.

It also reinforces Colep Packaging’s value proposition to the market as the preferred partner for metal packaging solutions, both in tinplate and aluminium.

As of 2025, the company previously known as ALM will adopt the corporate name Colep Packaging Barcelona, S.L. This plant will continue to be dedicated to the production of aluminium aerosols - a strategic segment for Colep Packaging - now with the support of a consolidated brand in the market.

According to Paulo Sousa, Colep Packaging’s CEO,"This integration is a testament to our commitment to growth, innovation, and collaboration. By uniting teams and embracing new possibilities, we are paving the way for a future where excellence and sustainability in packaging solutions go hand in hand.”

Colep Packaging's industrial infrastructure is currently based in five locations: Vale de Cambra, Portugal; Kleszczów, Poland; Navarra and Barcelona, Spain; and Querétaro, Mexico.

The new section shows the detailed filling machines offer highlighting the main features of each typology.

Coster Tecnologie Speciali S.p.A., multinational provider of spray packaging solutions and aerosol filling equipment since 1963, announced today the launch of its new website section of the Machinery Division. Designed to be more interactive and user-friendly, as you can surf the portfolio in just one-click, the latest online page shows detailed information about various machinery typologies and features. Located in Pero, close to the centre of Milan, Coster Machinery Division operates on a global scale.

The division caters to several industries, including personal care, cosmetics, household, technical, and pharmaceuticals. The Machinery Division product offering extends from semi-automatic machines, indexing machines and ancillaries, to fully integrated rotary lines. Coster has a range of machines dedicated to the pharmaceutical industry as well, such as Bag-on-Valves and asthma inhaler valves (pMDI) filling lines. "We usually design customised solutions for our clients. On-site inspections, fully dedicated pre and post sales services, FAT also performed remotely are all steps of a standard path in our line development. The new section of our website could help prospects and customers to get the very first briefed information and drive the development of their next filling lines" said Pierpaolo Bossi, Head of Sales Machinery at Coster. In addition to designing and manufacturing tailored solutions, the Machinery Division stands also for the following services: on-the-job trainings directly on the machine, technician intervention on-site, machine status assessment, programmed maintenance and spare parts shipment in 24h via courier. Each Coster machine is developed under the European directive 2006/42/EC (Machinery Directive), which aims at the free market circulation on machinery and at the protection of workers and consumers using such machinery.

As part of its sustainability roadmap, Coster Group is committed to achieving landfill-free waste management by 2026 worldwide. Through detailed mapping of all waste inventories and relevant streams, the Group has succeeded in meeting its goal in each of the eight production plants in Trentino, and the Zero Waste to Landfill certificate is a significant milestone in this ambitious journey.

Coster Group is proud to announce that it has successfully achieved the prestigious Zero Waste to Landfill (ZWL) certificate. This significant accomplishment follows a rigorous audit conducted by Intertek, which confirmed the company's commitment to environmental sustainability and responsible resource management.

By implementing a comprehensive waste management system and adopting innovative practices, Coster Group has achieved an impressive 99,995% waste diversion rate from landfill, far surpassing the minimum requirements of the ZWL certification.

This remarkable achievement applies to each of the eight Coster Group’s production sites in Trentino, including the companies Coster Tecnologie Speciali S.p.A., CosterPlast and TecnoCoster, demonstrating the Group’s dedication to minimizing its environmental footprint on a global scale. While this initial phase focused on Italian sites, the Group's ambitious program extends beyond national borders. By 2025, it aims to achieve landfill-free certification across all its sites in Europe and by 2026 worldwide.

From June 2023 to June 2024, the eight sites disposed of up to 1860 tons of waste as follows (the Diversion Rate of waste from landfill and incineration amounts to 99.995%):

Waste to Landfill Rate = 0 %

Waste to Incineration Rate = 0,005%

Waste to Recover/Recycle Rate = 98,407%

Waste to Energy Rate = 1,588%

The certification attests Coster Group's investments in advanced technologies for waste treatment and recovery, its commitment to engaging all employees in the waste reduction process through comprehensive training programs and the strategic partnerships with qualified recycling companies as well. By implementing these initiatives, the company aims to ensure maximum transparency on the management of the waste and its life cycle after disposal.

“Achieving the Zero Waste to Landfill certificate is a significant milestone for our Group. While we are proud of this result, we recognize that our journey towards a more sustainable future is ongoing. We are actively working to further optimize our processes, explore emerging technologies, and collaborate with partners to achieve the ambitious goals set in our Sustainability Roadmap. Our aim is to minimize the landfill disposal of waste we generate in our factories, warehouses and offices to less than 1% at Group level by 2026, maximizing resource recovery and contributing to the circular economy” states Andrea Raineri, Coster Chief Innovation & Sustainability Officer.

With its unique design and locking function, it is the ultimate solution for perfumes on-the-go.

Coster Group, leading multinational provider of spray packaging solutions and filling equipment, unveils ON-OFF, the revolutionary system that changes the traditional act of applying fragrances.

Thanks to its innovative design, ON-OFF is a smart system that combines the pump, collar and cap in a single solution, making it a valuable alternative for a disruptive yet functional perfumery packaging.

Designed especially for those brands that aim to create a fragrance that can be taken anywhere, even when travelling, ON-OFF differs from classic perfume pumps and spray actuators in that it does not require an overcap and has a locking function, which makes it possible to have a fragrance that is safe and therefore convenient for the dynamic consumer.

A further key feature is the flexibility of the system, as the collar easily fits all types of flasks and aluminium cans with a diameter of 15 mm and a dosage of 90 and 120 mcl.

ON-OFF guarantees a high level of spray quality as it is based on the reliable Coster MPE perfumery pump engine used by many perfumery customers worldwide.

The system embraces sustainability as it does not require an additional overcap, also reducing overall manufacturing complexity.

In addition, it provides the benefit to brands of sourcing all materials from a single supplier, thereby also reducing the complexity of production.

ON-OFF changes the traditional act of perfume application, in fact, the dispensing mechanism can be activated in a single touch and, thanks to a laser-printed mark on the collar indicating the open position, it makes the experience even simpler and more intuitive. Adding a new feature to perfumes is now possible for brands to address to consumers who are always on the move and look for convenience.

This all-in-one solution is also very practical because there is a sticker on the top that indicates when the mechanism is locked or not, and therefore when it is possible to dispense the fragrance. This built-in option makes it easier for brands to find themselves with the markings already present on the component. The system is very immediate: when it is on “off”, spraying is not allowed and it is necessary to rotate 90° clockwise to unlock the system. On the opposite, when it is no longer locked and it is therefore on “on”, it is necessary to rotate 90° counterclockwise to lock the system.

From an aesthetic point of view, ON-OFF is available in 40 standard colours, either glossy or matt, with the possibility of developing customised colours on request.

"We are proud to have re-launched ON-OFF on the market in a completely revolutionary new version. This is a project we have been working on for a long time and which we care about. Analyses of the perfumery market combined with those of packaging led us to the conclusion that there was no such system that could combine a perfumery pump with a locking system, all designed for the consumer always on the move. We worked together with the technical and innovation and sustainability teams to come up with an innovative solution. Hence ON-OFF was born. We will officially present it at the next Luxepack in Monaco in September and we hope to see it on the shelves very soon.” states Riccardo Mantelli, Coster Packaging Commercial Director.

Coster Group, a leading multinational provider of spray packaging solutions and aerosol filling equipment, today presents its Sustainability Report 2023, a document that outlines the company's achievements and future goals towards an ever more sustainable future, which follows the path of transparency and stakeholder engagement undertaken in 2017.

The seventh edition of the report is divided into three main areas: environment, people and community, and products, offering a comprehensive overview of the Group’s commitments and results.

In 2023, the company celebrated its 60th anniversary. It has been a year of transformation for Coster, marked by the implementation of a renewed governance that modifies the Group’s Purpose and Vision and the definition of an ambitious Sustainability Roadmap 2023-2030.

The company has strengthened its effort to transparency as well, maintaining after 7 years important recognitions from CDP, EcoVadis and Ellen McArthur Foundation and validating its emission targets according SBTi criteria and in line with the 1.5°C trajectory.

Coster's investments in energy efficiency and the purchase of renewable energies have led to significant progress in environmental protection, as mentioned in the report. In fact, the company has managed to reduce total energy consumption by 2% and keep the share of electricity from renewable sources to 84%. In addition, Scope 1 and Scope 2 market-based emissions have decreased by 36% compared to 2021.

During 2023 Coster started the project "Zero Waste to Landfill" that will lead to obtain this certification for the whole company before the end of 2026. All the actions taken regarding waste management have seen significant results as well: a 4% reduction of the total waste compared to the previous year and a 78% cut in waste sent to landfill.

The Group’s continuous dedication to product innovation is expressed through the development of sustainable and high value-added solutions. In 2023, many new products developments were launched including sustainable solutions.

Coster confirms its responsibility towards its employees by investing in trainings and workplace safety. In 2023, 33% more training hours were provided compared to the previous year and no high-consequences work-related injuries have been registered. Also, a 36% reduction in recordable accidents are further evidence of the company's dedication. Moreover, a three-year programme (2023-2025) was launched that will enable all sites to be audited according to SMETA IV pillars’ standards.

After two years of “Joining Forces with Suppliers”, Coster boasts of the evolution of its suppliers' sustainability, which has also been verified by very successful on-site quality and sustainability audits.

The company has implemented a community development policy that aims to respect the territory, create job opportunities, support the local economy and promote the well-being of its employees and surrounding communities. Social initiatives include CosterCares and Coster Academy among others, undertaken by the Group to collaborate with local associations for solidarity, social and charity projects.

“2023 was a year of great challenges and equally great opportunities. We have worked with determination to reduce our environmental impact, invest in our employees and develop innovative solutions that meet the needs of the market and society. Our commitment to sustainability is constant and the results achieved are the stages of a journey that see us at the forefront in building a better future.” States Andrea Raineri, Coster Head of Innovation & Sustainability.

On March 13, Nicholas Georges, Senior Vice President, Scientific & International Affairs, participated in a hearing conducted by the New York State Department of Environmental Conservation (NYSDEC) on proposed amendments to 6 NYCRR Part 494, Hydrocarbon Standards and Reporting, expressing concerns with the proposal because of challenges for industry, as well as consumers and workers who use aerosol products and small containers of automotive refrigerant and the state regarding compliance with federal requirements, such as attainment with the National Ambient Air Quality Standards (NAAQS) for ozone.

On March 19, HCPA submitted a letter to NYSDEC that included more details about these concerns with the proposed amendments. HCPA collaborated with the Center for the Polyurethanes Industry (CPI) and the Personal Care Products Council (CPSC) to amplify industry’s concerns.

HCPA and Allied Trade Associations Meet with NYSDEC on 1,4-Dioxane

On April 2, HCPA, the American Chemistry Council (ACC), the American Cleaning Institute (ACI), the Consumer Brands Association (CBA), and the Personal Care Products Council (PCPC) met with the New York State Department of Environmental Conservation (NYSDEC) to discuss proposed amendments to the regulations to limit 1,4-dioxane in household cleansing, personal care, and cosmetic products sold in New York.

During the meeting, the trade associations underscored points made in previous letters submitted to NYSDEC, including opposition to expanding the definition of household cleansing products, the need for clarity on the definition of a manufacturer, and the sustainability of concentrated products.

HCPA Submits Comments on California SB 343 Implementation

On April 2, HCPA submitted a letter to the California Department of Resources Recycling and Recovery (CalRecycle) on the Preliminary Findings Report for SB 343, California’s Truth in Labeling law for recyclable claims. The Preliminary Findings Report contains the draft required characterization study of material types and forms that routinely become feedstock used in the production of new products and packaging.

HCPA is concerned that the report does not provide sufficient clarity to businesses on how to avoid making a “deceptive” recycling claim in California.

HCPA’s comments urged CalRecycle to harmonize the material type and form categories in the SB 343 report with those used in SB 54 (Extended Producer Responsibility) recyclable determinations, revisit the analysis of the recyclability of steel packaging, and include information on all statewide criteria for recyclability. Significant updates are necessary to support regulatory certainty for businesses and to improve consumer understanding of what and how to recycle.

HCPA Meets with FCAC on Proposals to Amend International Fire Code

Three proposals have been submitted to amend the aerosol chapter for the next edition of the International Fire Code (IFC). Two of these proposals are from HCPA to align the IFC with recent amendments to NFPA 30B, Code for the Manufacture and Storage of Aerosol Products. The third proposal was submitted by the Fire Code Action Committee (FCAC), a group of fire officials.

The FCAC proposal would amend the definitions and categorization of various aerosol products to align with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The basis for this amendment is that fire officials want to verify the proper design of buildings and warehouses. Fire officials typically have information about flammability from the Safety Data Sheet; however, the GHS was not developed with fire protection schemes in mind and could result in inadequate fire protection, which is concerning to HCPA and other stakeholders.

On April 2, Nicholas Georges, Senior Vice President, Scientific & International Affairs, Jim Bloome, R.A. Jones, and Dave Fredrickson and Bill Koffel, two of HCPA’s fire code consultants, met with representatives from FCAC’s Hazardous Materials Work Group to discuss their proposal.

While FCAC still plans for the proposal to be heard at the next International Code Council (ICC) Committee Action Hearings, they did agree to work with HCPA to amend the proposal over the next few months to ensure it includes adequate fire protection.

HCPA Presents at Aerosol Summit

On April 9, Nicholas Georges, Senior Vice President, Scientific & International Affairs, presented at the Aerosol Summit in Nashville, Tennessee, to provide an update on the Aerosol Recycling Initiative and other activities that HCPA has undertaken on behalf of the aerosol industry, such as fire and building codes and inhalant abuse.

HCPA Participates in Fire Code Hearings for International Code Council

The International Code Council (ICC) Committee Action Hearing are currently taking place in Orlando, Florida. HCPA previously submitted two proposals regarding the storage of aerosol products that would align the next version of the International Fire Code (IFC) with the National Fire Protection Association (NFPA) 30B, Code for the Manufacture and Storage of Aerosol Products. However, a third proposal was submitted by the Fire Code Action Committee (FCAC) that would amend the IFC for aerosols to align with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

HCPA knows that the FCAC proposal would result in inadequate fire protection for several different aerosol product formulations. On April 10, HCPA was successful in getting the FCAC proposal disapproved and will continue to work with stakeholders to ensure the safe manufacture and storage of aerosol products.

Aerosol Recycling Initiative Details Economic and Environmental Benefits of Recycling Aerosols

On April 22, the Aerosol Recycling Initiative published the Executive Summary to a white paper that will be released in May, which details the campaign’s initial-phase activities and data gathered to date to establish the aerosol can’s recycling story.

Nicholas Georges Meets with Industry Stakeholders in Australia

Recently, Nicholas Georges, Senior Vice President, Scientific & International Affairs, participated in a series of meeting in Sydney, Australia.

On April 16, Georges met with representatives from Accord Australasia Limited to discuss priority industry issues, including chemicals of concern, digital labeling, inhalation abuse, plastics, and volatile organic compound (VOC) activity.

On April 17, Georges participated in the International Liaison Committee (ILC) meeting, which addressed various aerosol issues and opportunities, including designing for recycling, inhalation abuse, VOC regulations, and regional regulatory activity. The ILC is comprised of aerosol trade associations from around the world.

On April 18, Georges presented at the Aerosol Association of Australia’s (AAA) aerosol industry forum on the U.S. perspective on Extended Producer Responsibility (EPR) for aerosol products and the Aerosol Recycling Initiative. Georges also participated in a panel discussion with international allied trade associations about how aerosol associations are confronting challenges to the aerosol delivery technology.

On July 23, Nicholas Georges, Senior Vice President, Scientific & International Affairs, and Doug Raymond, from member company 3R, attended multiple meetings with staff from the California Air Resources Board (CARB).

The first meeting was with Ravi Ramalignam, Chief of the Consumer Products and Air Quality Assessment Branch, and his team about the upcoming CARB rulemaking for consumer products, including the next CARB product survey, photochemical reactivity, and potentially modifying definitions to provide clarity.

The second meeting was with Shannon Downey, Manager of the Consumer Products Enforcement Section, about enforcement trends, potential areas for clarification, and how industry can assist with enforcement.

Nicholas recommended that Shannon present to HCPA members during a webinar in late October/early November about CARB enforcement, advice to remain compliant, and how companies should handle a penalty letter, which Shannon gladly agreed to do.

HCPA Meets with OEHHA on Prop 65

On July 23, Nicholas Georges and Doug Raymond met with David Edwards, Acting Director of the Office of Environmental Health Hazard Assessment (OEHHA), and Julia Dolloff, the Office’s new ombudsman. They discussed updates to the Prop 65 program, including the short-formal labeling proposal, and the need for more safe harbor limits.

HCPA Attends Oregon DEQ Meeting on VOC Regulations for Consumer Products and AIM Coatings

On August 1, the Oregon Department of Environmental Quality (DEQ) conducted its first meeting with the Advisory Committee on potential volatile organic compound (VOC) regulations for consumer products and architectural and industrial maintenance coatings (AIM Coatings). HCPA is a member of the Advisory Committee.

To start the meeting, Oregon DEQ discussed the desire to adopt a regulation more stringent than the Environmental Protection Agency (EPA) to improve air quality. While Oregon does not have any areas currently in nonattainment with the Ozone National Ambient Air Quality Standards (NAAQS), the Department would like to adopt rules proactively rather than being required by the EPA.

In the meeting, Nicholas Georges, Senior Vice President, Scientific & International Affairs, Doug Raymond, 3R, and Rhett Cash, American Coatings Association (ACA), stressed the importance of regional consistency, urged the Department not to hybridize model rules, and shared insights about both regulations so that DEQ and other stakeholders could be better informed.

Georges, Raymond, and Cash requested a follow-up meeting to discuss these potential regulations in more detail.

HCPA Meets with EPA on AIM Act

On August 5, Nicholas Georges, Senior Vice President, Scientific & International Affairs, and Doug Raymond, 3R, met with the EPA regarding the labeling and recordkeeping provisions from a regulation finalized in 2022 under the Technology and Transition authority of the American Innovation and Manufacturing (AIM) Act.

Georges and Raymond shared industry concerns about compliance challenges with disclosure requirements, including the effective date of January 1, 2025, especially for pesticide products which do not currently have a pathway for compliance. HCPA has underscored this problem since the rule was finalized and has routinely met with the Agency for updates.

HCPA Presents about the Aerosol Recycling Initiative on Sonoco Webinar

On August 7, Molly Blessing, Nicholas Georges, and Scott Breen from the Can Manufacturers Institute (CMI) presented about the Aerosol Recycling Initiative and the recently released white paper during a webinar hosted by member company, Sonoco.

The aim of the webinar was to educate more people inside and outside the aerosol industry about the Initiatives to recruit additional partners and sponsors. Molly, Nicholas, and Scott discussed the purpose and goals of the Initiative, the project’s work to date and findings, the next steps, and how companies can get involved.

HCPA Submits Letter to PHMSA on the Development of General Investigative Questions

On August 12, HCPA submitted a letter to the Department of Transportation (DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA) regarding the development of questions that may be used by PHMSA’s Office of Hazardous Materials Safety (OHMS) field operations personnel when investigating potential general safety issues.

HCPA supports PHMSA’s effort to establish a uniform and consistent approach to investigations, regardless of region or investigator. However, the letter requested certain clarifications to improve the approach.

HCPA Submits Letter to Canada on HFC Regulatory Alignment

HCPA recently submitted a letter to Environment and Climate Change Canada (ECCC) in response to a consultation of Canada’s Ozone-depleting Substances and Halocarbon Alternatives Regulations (ODSHAR).

HCPA continues to advocate for alignment between Canada’s regulation and the Environmental Protection Agency’s (EPA) implementation of the American Innovation and Manufacturing (AIM) Act. Canada implemented volatile organic compound (VOC) regulations based on regulations that were developed in the U.S., so it is critical that compliance tools, such as Hydrofluorocarbons (HFCs), are treated similarly.

024 CARB Enforcement Webinar

October 29 | 1:00 – 2:30 pm ET

For more than 35 years, the California Air Resources Board (CARB) has regulated the volatile organic compound (VOC) content of consumer and commercial products. Industry has invested significant time and resources into researching and developing new and reformulated products that meet CARB’s VOC limits. Working together, government and industry have ensured that Californians have access to the products they need for living safe and healthy lives while improving air quality in the state.

Join Shannon Downey, Manager of the Consumer Products Enforcement Section at CARB, and Doug Raymond, the owner of Raymond Regulatory Resources (3R), to better understand how CARB handles enforcement, tips on how to remain compliant, and what to do if your company receives a notice of violation letter.

Steve Caldeira, President & CEO, and Mike Gruber, Executive Vice President, Government Relations & Public Policy, were recently named to The Hill’s Top Lobbyists 2024. This is the eighth consecutive year that Caldeira has been included on the list and the tenth time overall. This is the third time that Gruber has received this recognition.

HCPA Submits Comments to EPA on Proposal to Add 16 Individual PFAS and 15 PFAS Categories to TRI

On December 9, HCPA submitted comments to the Environmental Protection Agency (EPA) on a proposal to add 16 individual PFAS and 15 PFAS categories to the Toxic Release Inventory. The comments focused on concerns with the lack of a de minimis threshold and the category approach.

Regarding the de minimis level, HCPA said that the substantial impact of eliminating this exemption has not been adequately captured in the proposed rule. Regarding the category approach, HCPA encouraged the Agency to reconsider this approach since it applies to such a broad category of chemicals or ensure that the category is well-defined and that analytical measurements are sufficiently robust for all substances within it.

EPA Finalizes Risk Management Rules for TCE, PCE, and CTC Under TSCA

The EPA recently finalized the risk management rules for trichloroethylene (TCE), perchloroethylene (PCE), and carbon tetrachloride (CTC) under the Toxic Substances Control Act (TSCA).

TCE is used as a solvent in consumer and commercial products, including cleaning and furniture care products, degreasers, brake cleaners, sealants, lubricants, adhesives, paints and coatings, arts and crafts spray coatings, and in the manufacture of some refrigerants. Safer alternatives are readily available for most of these uses. The Agency is finalizing its prohibition on all uses of TCE, more than likely within one year.

PCE is a solvent used in brake cleaners and adhesives, commercial applications such as dry cleaning, and many industrial settings. Safer alternatives are readily available for most of these uses. The Agency’s final risk management rule requires companies to rapidly phase down manufacturing, processing, and distribution of PCE for all consumer use and many uses at industrial and commercial workplaces, which is expected to happen within three years.

CTC is a solvent used in commercial settings as a raw material for producing other chemicals, like those in refrigerants, aerosol propellants, and foam-blowing agents. The Consumer Product Safety Commission (CPSC) banned the use of CTC in consumer products in 1970; however, certain uses of CTC were allowed to continue under the Workplace Chemical Protection Program (which includes inhalation exposure limits and dermal protections), including processing as a reactant in the production of hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), hydrofluoroolefins (HFOs), and perchloroethylene (PCE).

HCPA Meets with CPSC Chair Hoehn-Saric and Commissioner Boyle

On December 19, Nicholas Georges, Senior Vice President, Scientific & International Affairs, met with the Consumer Product Safety Commission (CPSC) Chair Hoehn-Saric and Commissioner Boyle to discuss the Agency’s proposal to ban aerosol dusters containing HFC-152a and/or HFC-134a.

In the meeting, Nicholas addressed the safety of aerosol dusters and propellants, the dangers of inhalant abuse, the industry’s commitment to addressing inhalant abuse and other intentional product misuse, and HCPA’s alternative proposal to the Commission’s proposed ban.

HCPA and ACA Present on VOC Regulations to Oregon DEQ Advisory Board

On December 16, Nicholas Georges and Rhett Cash from the American Coatings Association (ACA) gave a presentation to the Oregon Department of Environmental Quality (DEQ) Rulemaking Advisory Committee on the history of volatile organic compound (VOC) regulations for consumer products and architectural coatings; differences between the various Ozone Transport Commission (OTC) Model Rules and CARB’s regulations; the Alternative Control Plan (ACP); the Innovative Products Exemption (IPE); and chemicals of concern.

For consumer products, Oregon DEQ is considering alignment with either the OTC Phase IV Model Rule, OTC Phase V Model Rule, or CARB’s regulation. Nicholas and Rhett discussed the need for regional alignment and the challenges of aligning with CARB given the numerous rulemakings that the agency undertakes which push the boundaries of technical feasibility.

Oregon DEQ is expected to propose a rule in summer 2025.

CARB Launches Survey of Consumer and Commercial Products

On December 3, the California Air Resources Board (CARB) formally initiated the 2023 Consumer and Commercial Products Survey (Survey), with the launch of the Consumer Products Reporting Tool (CPRT). As part of this, CARB also published instructions, appendices, video resources, and a list of frequently asked questions to assist industry with reporting.

On December 5, CARB hosted a webinar with industry stakeholders to explain the amendments to proposed list of categories to be surveyed and other modifications, as well as review the CPRT and answer questions.

The deadline to submit information to CARB is April 8, 2025. However, there are noticeable differences between this survey process and the 2013 – 2015 Surveys. To assist members, HCPA will be hosting meetings every two weeks to provide relevant updates and for companies to share questions and concerns with the Survey.

Wednesday, January 10

Wednesday, January 24

1:00 - 2:00 pm EST

HCPA will host a two-part webinar series to provide attendees with the tools to determine legal and regulatory reporting requirements and perform due diligence to be compliant with the PFAS reporting rule.

Join Michael Boucher, a Partner at Steptoe, in part one as he explains the regulatory requirements of the rule, including the statutory basis for the rule, the substances subject to the rule, the reportable data elements, and timeline to report. There will also be a discussion on the “extent known to or reasonably ascertainable by” the manufacturer according to the rule.

Part two will be led by Sweta Ojha, Ph.D., toXcel, LLC, who will explain the due diligence activities that companies will need to perform to satisfy the requirements of the rule. The presentation will also include examples to illustrate the complexity and potential diverse scenarios a company could encounter.

HCPA Submits Comments to EPA on Safer Choice Standard Update

On January 16, HCPA submitted comments to the EPA on proposed updates to the Safer Choice standard. The standard identifies the requirements that products and their ingredients must meet to earn the Safer Choice label or Design for the Environment (DfE) logo.

HCPA’s comments emphasized the value of Safer Choice for promoting safer and more sustainable chemistry and commended the program for seeking to encourage sustainability in products in a more holistic manner.

However, HCPA raised concerns that Safer Choice may not have the resources to appropriately assess some of the new criteria being proposed, specifically the packaging criteria and performance testing for non-FIFRA claims on DfE products. The comments also discussed the program’s proposed approach to surfactants, the importance of microorganism-based products and factors to consider in their evaluation criteria, and the language of the sample partnership agreements. For more information, please contact Molly Blessing, Director, Sustainability, at mblessing@thehcpa.org.

Molly Blessing Promoted to Vice President, Sustainability & Product Stewardship

Molly Blessing has been promoted from Director of Sustainability to Vice President of Sustainability & Product Stewardship, effective February 15.

Over the last two years, Molly developed and launched HCPA’s Sustainability & Product Stewardship Council (SPSC), which serves as a forward-looking, trusted voice, and acknowledged leader in driving product stewardship and sustainability efforts. The SPSC is dedicated to educating and empowering people to live more sustainable lives. Under Molly’s direction, the SPSC has addressed several business-critical issues on behalf of the industry. This includes environmental marketing claims, Extended Producer Responsibility (EPR), recycled content, and sustainable chemistry.

In addition to managing these initiatives, Molly serves as the Division Staff Executive (DSE) for the Air Care Products Division and co-leads the Retail Engagement Work Group (REWG) with Dr. Steve Bennett, Executive Vice President, Scientific & Regulatory Affairs.

HCPA Meets with PHMSA on Aerosol Products

On January 26, Nicholas Georges, Senior Vice President, Scientific & International Affairs; Andy Franckhauser, Senior Scientist, Procter & Gamble; and Rodney Prater, Principal Packaging Engineer, S.C. Johnson, met with Shane Kelley, Director of Standards and Rulemaking, and Steven Webb, Transportation Specialist – International Program, from the Department of Transportation (DOT) Pipeline & Hazardous Materials Safety Administration (PHMSA) to discuss international efforts within the United Nations Sub-Committee of Experts on the Transport of Dangerous Goods (UNSCETDG) regarding aerosol products, including the definition of an aerosol and opportunities and challenges for this product category.

HCPA has a long-standing history of working with PHMSA – both in private meetings and at public sessions – on proposals presented at the UNSCETDG to help regulators understand the industry’s position on certain issues.

HCPA and COSTHA Meet with PHMSA

On February 20, HCPA, the Council of Safe Transportation of Hazardous Articles (COSTHA), and representatives from member companies Plastipak, Procter & Gamble, Reckitt, and SC Johnson met with officials from the Department of Transportation (DOT) Pipeline and Hazardous Materials Safety Administration (PHMSA) to discuss the use of post-consumer recycled (PCR) content in plastic aerosol containers.

Currently, the Hazardous Materials Regulations (HMR) does not allow for the use of PCR in plastic aerosol containers. In the meeting, HCPA members discussed the data developed to support the inclusion of PCR in plastic aerosol containers and the potential of a petition for regulatory amendments. While PHMSA seemed open to a petition, the exact language on revising the regulations needs to be discussed further.

HCPA will continue to collaborate with COSTHA on this effort, which will likely result in both a special permit application and petition for amending the HMR.

On May 30, HCPA and the Can Manufacturers Institute (CMI) published a White Paper through the Aerosol Recycling Initiative that presents a year’s worth of data and analysis regarding the accessibility, understanding, and safety of recycling aerosol cans in the U.S. in an effort to increase the recyclability of these products for the benefit of the environment and the economy.

Following this work, the campaign will enter Phase 2 in its effort to meet the two 2030 goals that were established at the start of the Initiative: (1) Achieve at least an 85 percent recycling access rare for all aerosol cans and (2) Label at least 90 percent of aerosol cans as recyclable with messaging about how to properly do so.

Thank you to the following sponsors for their generous support of the White Paper and the Initiative’s first year Gamble Company, PLZ Corp, Reckitt, SC Johnson, Sherwin Williams, Sonoco, Summit Packaging Systems, and Trivium Packaging.

Update on Currently Unavoidable Uses for PFAS in Maine