SARIBEKIR AMBALAJ was founded in 2004 and is dedicated to the metal packaging industry. The Sarıbekir Ambalaj plant, which manufactures two- and three-piece tin cans, easy-open lids, twist-off closures and aerosol cans, is located in the Balıkesir Organized Industrial Zone and has its headquarters in Istanbul.

At Sarıbekir Ambalaj, 50 years of know-how in can manufacturing is combined with state-of-the-art technology. Regular improvements in research and development make the company a reliable and innovative partner in the market.

Sarıbekir Ambalaj still has a strong presence in Europe, the Middle East, North Africa and the Black Sea region. Nevertheless, the company intends to grow further in the future, expand its product range and open new production facilities in other locations.

The needs of the customers always come first. With innovations and constant further development of the product range, the company tries to meet customer expectations on a daily basis. Reasonable prices and fast delivery are terms that characterize the company.

Quality assurance and quality control are very important at Sarıbekir Ambalaj. Quality controls are carried out using state-of-the-art technology and computer-controlled measuring devices.

SARIBEKIR AMBALAJ started production of three-piece aerosol cans made of tinplate in mid-2018 using the latest technology investment. The aerosol cans in diameters of 45, 52, 57 and 65 and in various lengths are produced after a 100% leak test in accordance with FEA standards.

In addition, SARIBEKIR AMBALAJ wants to stand out from the competition with high print quality and uses a printing technology that can print 4+2 colors wet-on-wet, 6 colors UV-cured wet-on-dry and 8 colors UV-cured wet-on-dry with UV varnish. The result is a clearer and more vibrant print quality. Contract printing services are also offered. The printing and varnishing equipment is state of the art and is characterized by high speed and precision.

Metal packaging from SARIBEKIR AMBALAJ is lightweight and highly durable. They are resistant to physical impact. This makes them easy to store and cost-effective to transport. The imprints that can be applied to the metal packaging increase the attractiveness of the product in the packaging and support the manufacturer in marketing. As metal packaging can be produced in different sizes and shapes, it ensures that the product is packaged in the desired size.

The British Aerosol Manufacturers’ Association has announced the winners of the BAMA Awards 2024, sponsored by Sarten Ambalaj.

On the 16th October, at Cheshire’s Carden Park Hotel, winner, runner up and highly commended awards from five different categories were presented to successful entrants.

Aerosol of the Year Winner: Church and Dwight’s Batiste 24H Dry Shampoo

In pursuit of innovation and technical proficiency in design and dispensing, the judges were particularly impressed with the fragrance innovation behind Church & Dwight UK’s Batiste 24H Dry Shampoo, declaring it a clear winner. Judges’ comments included: “A true piece of innovation behind the encapsulated fragrance. I imagine this will be of real interest to active consumers.”

Highly Commended – Jago Pro’s 2-Phase Mask

Receiving a ‘highly commended’ in the Aerosol of the Year category, the judges remarked on the originality of the product design of the 2-phase mask: “A novel idea not seen before, offers a very smooth texture when applied on the skin and easily removed after application.”

Highly Commended – Jago Pro’s Whipped Sunscreen Mousse SPF50

Again, earning praise from the judges, Jago Pro collected another ‘highly commended’ accolade for its Whipped Sunscreen Mousse. Judges’ comments included: “Easy to dispense, offers high level sun protection and a little bit goes a long way.”

Sustainability Award Winner: Unilever’s OMEGA Light Weight DWI Aerosol can

Another standout winner at the awards was Unilever’s light weight DWI aerosol can which attracted commendation on its impressive material reduction. Judges’ comments: “The high percentage of recycled aluminium used for the coil during production and the significant reduction in can weight make this an all-round win for sustainability.”

Runner Up: Church & Dwight UK Ltd - PCR-ed Batiste Packaging

Church & Dwight also picked up a runner up award for its PCR Batiste Packaging. Judges’ comments: “A well thought-out and flexible solution that accommodates both changing regulations and up-to-date recycling messages for consumers.”

Highly Commended: Massilly UK’s ‘Sustaining Sustainability’

Massilly received a highly commended for its Sustaining Sustainability entry, reflecting the company’s commitment to improving social, environmental and human relations. Judges’ comments: “A strong reminder of the merits of supporting and encouraging suppliers, large and small, to build on their sustainable commitments.”

Process Safety & Training Winner: Massilly UK’s Kascade

Massilly topped the category with its data collection tool, Kascade, designed for continuous improvement action plans. Judges’ comments: “One of the main reasons this simple, but effective process stands out is because of its ability to be transferred across multiple industries.”

Runner Up: Pharmatec Solutions’ Innovative Two-stage Powder Filling Process for Sustainable & Efficient Aerosol Delivery

Judges were especially impressed with the fastidious process behind Pharmatec’s powder filling process, also noting the numerous benefits to the pharmaceutical industry. They commented: “The process has been meticulously thought-out resulting in a series of sustainable manufacturing and filling advantages for the pharmaceutical industry.”

Aerosol Packaging Winner: Aptar Beauty, Twist-To-Lock Aerosol Family: Tina, Nora, Ringo

A firm winner in the packaging category was Aptar Beauty’s Twist-to-lock range, attracting positive observations from the judges on the application, sustainability and user experience benefits. Judges’ comments: “The range contains some sound ergonomic features like the audible click which offers a satisfying user experience and may be of benefit for those with visual impairments.”,

Runner Up: Coster Aerosols’ Metered Dose BOV

A strong runner up, Coster’s Metered Dose BOV received favourable mentions from the judges on the solution’s adaptability and environmental merits. Judges’ comments: “A versatile solution compatible with a multitude of pharmaceutical and cosmetics formulations.”,

Eviosys wins Aerosol in Action Award

Three photographs were shortlisted for the Aerosol in Action category. These were displayed at the Forum for attendees to pick their favourite. Announced at the ceremony, the winner was Eviosys’ ‘The endless cycle: wind turbine through an aerosol can top’ – a striking image of a steel cap with a wind turbine prominent in the background. The image will feature as a front cover of the BAMA Annual Report 2025, and it will also appear in World Aerosols magazine.

Tony Brealey collects Special Recognition Award

Collecting the Special Recognition Award this year was Tony Brealey, Managing Director and co-owner of Reabrook Ltd. and former BAMA Chairman. Patrick Heskins, BAMA Chief Executive said of Tony: “This award is thoroughly deserved, not only for what Tony has done for BAMA during his time on the Board and as Chair, but also for his incredible achievements with Reabrook, taking the business from strength to strength.”

In today's business landscape, the collection and analysis of environmental data are gaining ever more importance. Companies are facing demanding sustainability regulations, while consumers are demanding greater transparency regarding the carbon footprint of the packaging they purchase. thyssenkrupp Rasselstein, Germany’s sole tinplate manufacturer, is addressing this need by sharing its expertise in Life Cycle Assessment (LCA) with its customers, the packaging manufacturers. LCA is a methodical approach used to evaluate the environmental impact (such as CO₂eq.) of a product throughout its entire life cycle. By providing detailed emissions data, thyssenkrupp Rasselstein equips its customers with valuable insights into the environmental performance of tinplate. Furthermore, thyssenkrupp Rasselstein offers support to customers in calculating an LCA for their own products.

“We frequently encounter customers who are keen to understand the carbon footprint of their products and identify opportunities for CO₂ savings within their production processes. In tinplate production, we recognized early on the importance of evaluating the entire product life cycle, which is why LCA has become a core component of our sustainability strategy. LCA is now embedded in our product development process from the very beginning stages,“ says Dr. Linda Kerkhoff, Development Engineer in the Materials, Applications, and Technology department at thyssenkrupp Rasselstein GmbH.

Conducting an LCA offers numerous advantages for companies. The LCA of rasselstein® packaging steel has been verified and certified by Det Norske Veritas (DNV), one of the world’s leading certification bodies in business assurance. This certification ensures a reliable database and calculation methodology, facilitating transparent communication with end customers, enhancing competitiveness with other packaging materials, and serving as a foundation for the LCA of customer products. Overall, the LCA enhances transparency, offering valuable insights into production processes and their environmental impact, thereby enabling the development of more sustainable packaging solutions.

Analysis supported by a comprehensive energy management system

Over the past three years, thyssenkrupp Rasselstein has significantly expanded its expertise in LCA. The company, based in Andernach, has developed a comprehensive energy management system that provides the essential data foundation for conducting LCAs of tinplate production. Close collaboration with colleagues at the Duisburg steelworks, from which the hot-rolled strip for the production of tinplate is sourced, has established an additional data basis. “We have access to all relevant data sets, enabling us to calculate our product's environmental impact with precision,” says Dr. Linda Kerkhoff. This allows the packaging steel manufacturer to comprehensively represent the entire process in its LCA, from steel production at the Duisburg plant to the point when the tinplate leaves the Andernach facility for the customer.

In an LCA, emissions are categorized into three different scopes. Scope 1 covers all direct emissions generated on-site. At thyssenkrupp Rasselstein, this includes emissions from the combustion of natural gas. Scope 2 and Scope 3 are referred to as indirect emissions. Scope 2 encompasses emissions from the generation and procurement of electricity, natural gas, and steam. Scope 3 includes emissions from the upstream value chain, such as the extraction and production of raw materials like tin, iron ore, and steel/hot-rolled strip.

LCA makes CO2 savings potential visible

The LCA conducted by thyssenkrupp Rasselstein reveals a total carbon footprint of 2.45 t CO₂ eq./t of packaging steel. The majority of these emissions are attributed to the hot-rolled strip supplied by thyssenkrupp Steel Europe in Duisburg, classified as Scope 3 emissions. Throughout the packaging steel production process, Scope 1, 2, and 3 emissions are generated. At the Andernach site, Scope 1 and 2 emissions are being continuously reduced through ongoing energy efficiency initiatives, such as the construction of a more modern coating line and the implementation of innovative recuperators in the annealing lines.

Customers already have several ways to reduce the carbon footprint of food and aerosol cans. “For instance, manufacturers can opt for tinplate made from CO₂-reduced bluemint® Steel, which can directly cut their Scope 3 emissions from packaging steel by up to 62%. Further CO₂ reductions are achievable through the use of innovative products like rasselstein® D&I Solid and rasselstein® Solidflex, which allow for a reduction in material thickness,” explains Dr. Linda Kerkhoff. To further assist its customers, thyssenkrupp Rasselstein collaborates closely with them to examine their processes and products, offering to conduct a tailored LCA. This assessment identifies CO₂ savings potential and optimization opportunities and provides guidance on how to best implement these improvements. “Unlike external institutes that also offer LCAs, we have an in-depth understanding of our customers’ needs and what packaging manufacturers truly value. Our goal is to partner with our customers to showcase tinplate as a viable and sustainable packaging material for the future,” says Dr. Linda Kerkhoff.

In today's business landscape, the collection and analysis of environmental data are gaining ever more importance. Companies are facing demanding sustainability regulations, while consumers are demanding greater transparency regarding the carbon footprint of the packaging they purchase. thyssenkrupp Rasselstein, Germany’s sole tinplate manufacturer, is addressing this need by sharing its expertise in Life Cycle Assessment (LCA) with its customers, the packaging manufacturers. LCA is a methodical approach used to evaluate the environmental impact (such as CO₂eq.) of a product throughout its entire life cycle. By providing detailed emissions data, thyssenkrupp Rasselstein equips its customers with valuable insights into the environmental performance of tinplate. Furthermore, thyssenkrupp Rasselstein offers support to customers in calculating an LCA for their own products.

“We frequently encounter customers who are keen to understand the carbon footprint of their products and identify opportunities for CO₂ savings within their production processes. In tinplate production, we recognized early on the importance of evaluating the entire product life cycle, which is why LCA has become a core component of our sustainability strategy. LCA is now embedded in our product development process from the very beginning stages,“ says Dr. Linda Kerkhoff, Development Engineer in the Materials, Applications, and Technology department at thyssenkrupp Rasselstein GmbH.

Conducting an LCA offers numerous advantages for companies. The LCA of rasselstein® packaging steel has been verified and certified by Det Norske Veritas (DNV), one of the world’s leading certification bodies in business assurance. This certification ensures a reliable database and calculation methodology, facilitating transparent communication with end customers, enhancing competitiveness with other packaging materials, and serving as a foundation for the LCA of customer products. Overall, the LCA enhances transparency, offering valuable insights into production processes and their environmental impact, thereby enabling the development of more sustainable packaging solutions.

Analysis supported by a comprehensive energy management system

Over the past three years, thyssenkrupp Rasselstein has significantly expanded its expertise in LCA. The company, based in Andernach, has developed a comprehensive energy management system that provides the essential data foundation for conducting LCAs of tinplate production. Close collaboration with colleagues at the Duisburg steelworks, from which the hot-rolled strip for the production of tinplate is sourced, has established an additional data basis. “We have access to all relevant data sets, enabling us to calculate our product's environmental impact with precision,” says Dr. Linda Kerkhoff. This allows the packaging steel manufacturer to comprehensively represent the entire process in its LCA, from steel production at the Duisburg plant to the point when the tinplate leaves the Andernach facility for the customer.

In an LCA, emissions are categorized into three different scopes. Scope 1 covers all direct emissions generated on-site. At thyssenkrupp Rasselstein, this includes emissions from the combustion of natural gas. Scope 2 and Scope 3 are referred to as indirect emissions. Scope 2 encompasses emissions from the generation and procurement of electricity, natural gas, and steam. Scope 3 includes emissions from the upstream value chain, such as the extraction and production of raw materials like tin, iron ore, and steel/hot-rolled strip.

LCA makes CO2 savings potential visible

The LCA conducted by thyssenkrupp Rasselstein reveals a total carbon footprint of 2.45 t CO₂ eq./t of packaging steel. The majority of these emissions are attributed to the hot-rolled strip supplied by thyssenkrupp Steel Europe in Duisburg, classified as Scope 3 emissions. Throughout the packaging steel production process, Scope 1, 2, and 3 emissions are generated. At the Andernach site, Scope 1 and 2 emissions are being continuously reduced through ongoing energy efficiency initiatives, such as the construction of a more modern coating line and the implementation of innovative recuperators in the annealing lines.

Customers already have several ways to reduce the carbon footprint of food and aerosol cans. “For instance, manufacturers can opt for tinplate made from CO₂-reduced bluemint® Steel, which can directly cut their Scope 3 emissions from packaging steel by up to 62%. Further CO₂ reductions are achievable through the use of innovative products like rasselstein® D&I Solid and rasselstein® Solidflex, which allow for a reduction in material thickness,” explains Dr. Linda Kerkhoff.

To further assist its customers, thyssenkrupp Rasselstein collaborates closely with them to examine their processes and products, offering to conduct a tailored LCA. This assessment identifies CO₂ savings potential and optimization opportunities and provides guidance on how to best implement these improvements. “Unlike external institutes that also offer LCAs, we have an in-depth understanding of our customers’ needs and what packaging manufacturers truly value. Our goal is to partner with our customers to showcase tinplate as a viable and sustainable packaging material for the future,” says Dr. Linda Kerkhoff.

The British Aerosol Manufacturers’ Association has released its UK aerosol filling figures for 2023, showing that volume remained stable compared to 2022, despite geo-political developments, supply chain challenges and the cost-of-living crisis.

Personal care

The survey reveals that, as anticipated, the personal care sector made up the lion’s share of filling volume accounting for 74% of the total – up from 71% in 2022. Representing the mainstay of UK aerosol manufacturing, cosmetics and toiletries, grew by nearly 3% and individual categories, such as deodorant and antiperspirant, rose by 4 ½% and nearly 13 ½%, respectively. BAMA Chief Executive, Patrick Heskins says: “Most of the categories showing the biggest percentage shifts are the smaller ones, which have a tendency to fluctuate in line with how the year has been. For instance, self-tan more than doubled in volume and is a likely indicator of the rather wet summer of 2023.”

The filling of shaving products dropped again, signifying the ongoing trend seen since the early 2000s, and no doubt reflecting ongoing facial hair fashions which have supplanted the ‘wet shave’ in recent times. Patrick adds: “Despite the drop in filling volume this year, there are many new products coming on to the market to entice those still wet shaving to experiment with.”

Household and technical

In the household sector, macro environment factors again played a role as the post-Covid era likely affected the continued decline of hard surface cleaners. Also, from a peak of nearly 200 million in 2017, the volume of air fresheners produced in the UK dropped to 133 million in 2023. One major brand owner’s move to an “aerosol free” product during 2022/2023 may offer explanation for the significant swing. Also, the different ways fragrances can be released into the home environment has developed hugely over recent years, for example, auto spray systems which use aerosols and pump sprays as the delivery mechanism, trigger sprayers, reed diffusers, plug in devices, scented candles, and a whole host of other systems giving consumers a huge choice. Patrick says: “While there are increased household fragrance options available, the aerosol package still has a place in this market. Perhaps, the instant benefits aerosols bring when tackling pungent odours could be revisited.” In the technical categories, the growth of paint aerosols being filled continues on the upward trajectory it has enjoyed since the turn of the century. This, combined with stable volumes in automotive and industrial aerosol filling shows that the sector is strong, and that the aerosol dispensing system still offers lots of unique advantages compared to many other packaging formats.

Aluminium V Tinplate

The most significant change in the 2023 filling data compared to 2022 is the split between tinplate and aluminium aerosols. Of the 1.42 billion units produced during 2023, 543 million were made from tinplate, while the remaining 877 million were aluminium, producing a 62/38 percentage split. This sizable shift from 2022 suggests the impact of a move away from steel from a major brand owner, with other smaller brand owners and own label products likely following suit. Patrick Heskins says of the shift: “There has been an on-going trend for many years in UK aerosol manufacturing to move more into aluminium containers, 2023 shows a significant jump. Also, although it is still a relatively small percentage, it is also worth noting that the volume of plastic aerosols filled is on the increase.”

Summing up the figures for 2023, Patrick commends the overall ‘astonishing achievements’ of the industry to date: “BAMA continues to be proud of what all those involved in the UK aerosol manufacturing industry have accomplished along with their continued focus on innovation while upholding incredible standards of safety and quality.” “The volume filled in 2023 shows that aerosol dispensers are still very much a product which consumers want, need, and enjoy. I look forward to an even better 2024.”

On Wednesday 17th April, the British Aerosol Manufacturers’ Association (BAMA) will host its 2024 Innovation Day at the Royal Armouries in Leeds, UK.

Sponsored by contract filler and manufacturer, JagoPRO, the event is free to attend for Association members and non-members and will feature a comprehensive programme of expert industry speakers and exhibitors.

BAMA Chief Executive, Patrick Heskins says: “The very nature of innovation means no two Innovation Day events are ever the same. This year, visitors can expect a variety of new aerosol technologies, designs, processes and discussion points brought to the fore by our knowledgeable speakers. As an interactive event, the Innovation Day has also proven to be a valuable platform for networking and exchanging ideas.”

Promoting a variety of supply chain innovations across the aerosol industry, the speaker programme includes a wide range of presentation topics. Collectively, presenters will explore and provide insights on the future trends and possible directions for aerosol dispensers, new developments within aerosol inspection solutions, and quality and process control systems for the metal packaging industry.

New technological advances driving the capabilities of plastic aerosols, the history of the aerosol format and the importance of developing a clear innovation strategy are also key themes on the event schedule.

Sustainability will again be a key focus area with a talk on an innovative new propellant-free dispensing technology, sustainable innovation within the personal care market and the reduced CO₂ footprint and added functionality of next generation of aerosol cans. The recyclability and benefits of the plug-in can/valve system will be explored, and the subject of how low carbon steel aerosol cans can contribute to reducing CO₂ footprint will also feature in the speaker programme.

Members of the audience will be invited to put their questions to the presenters following each conference session in the Exhibition Hall. Visitors will also be able to view samples and prototypes, and observe demonstrations from Innovation Day exhibitors and other companies on the day.

The 2023 BAMA Awards dinner and ceremony, hosted again at Carden Park in the verdant Cheshire countryside, was a gleaming event, with a record number of attendees and a larger-than-ever number of entries.

Raquel Miranda, Head of Sustainability at Colep Packaging, who sponsored the event, welcomed the audience and handed out the awards on stage. The GP and comedian Paul Sinha posed with the winners in front of the BAMA backdrop.

We have captured the proud smiles of those receiving recognition in the attached photos and captured some of the Judges’ comments below.

Sustainability

Winner: Grundon, Asthma cartridges recycling

Judges’ comments: “It really addresses and solves an issue that hadn’t been tackled before”, “there is a minimal amount of gas left in each pack, but it’s environmental impact is significant especially looking at the millions of units used”, “the network of return points (pharmacies and hospitals) makes it easy for the user: as they collect the new inhalers, they can drop off the empty ones. It is likely that most empties will be captured”.

Runner Up: Precision, Stylish 52 actuator

Judges’ Comments: “It addresses the problem of how to recycle aerosols caps, which are usually mixed plastics, by making the whole thing out of one material but still maintains a similar spray performance” “The idea that making the cap shorter saves material is so simple, but so effective”.

Highly Commended: Salvalco with Mentholatum, Deep Freeze - Deep Heat

Judges’ Comments: “they have completely eliminated the LPG propellant, so they innovate mechanically to ensure a good spray, but also reformulated the content to keeps its properties”, “It actually works better than the original version…probably because there is more active ingredient dispensed”, ‘”the can is visibly smaller, so there’s also less material used, reducing the carbon footprint, but not so much smaller to put consumers off when placed on the shelf”.

Aerosol Packaging

Another clear winner for the Packaging category: the judges awarded first place to Coster Aerosols for their Digitally printed actuator. While the other entries had their own merits, the judges felt they were on a similar level, so no runner up was identified for this category.

Judges’ Comments: “From the point of view of visual impact, it is a game-charger’” “It opens up so many different opportunities”, “you can have the product on a lower shelf and still attract the shopper’s attention”

New Aerosol of the Year

Another category with a wide range of products entered, either marketed in the UK, or produced in the UK for export markets. It is probably the most interactive moment of the whole judging process, as we see mainly finished products which can be sprayed, smelled and tested, where the labelling is examined and the concept and degree of innovation assessed.

Winner: KDC/ONE Swallowfield, Mousse-to-Oil moisturizer

Judges’ Comments: “it is a sensuous experience when you use it, and it’s not greasy or dripping like an oil would be” “a beautiful creamy foam, you only need a tiny amount and the fragrance is pleasant but subtle, not overpowering like other products” “the effect on the skin is visible, and when you apply it, it’s a pampering experience’

Runner Up: Volcke Aerosol UK, Dry Foam Shampoo for Dogs

Everyone was surprised and excited by this entry, probably looking forward to the playful experience of covering a hairy animal in foam. Unfortunately, BAMA did not have anything to try the product on.

Judges’ Comments: “There are many spray products for pets, but none of them in a foam” “I would definitely try it on my dog” “people care more and more for their pet as a family member, it’s good that the company has thought about that and extended the range of dry shampoos to cover them too”.

Highly Commended: Church & Dwight, Batiste Leave-in Dry Conditioner

Church & Dwight deserved a commendation for their Dry Conditioner, which was found to really make a difference once applied to hair. One of the BAMA staff lent their just-washed mane for product testing.

Judges’ Comments: “hair is much smoother and soft to the touch” “it’s a good complement to the existing range, but it can be used on its own” “easy to apply, much quicker than the traditional conditioner which needs to be rinsed off”.

Process Safety and Training

This year’s winner, with a project focused on creating a seamless flow between the client’s needs and the supplier’s delivery, is Massilly UK for ‘The Coal Face’ program.

Judges’ Comments: “It’s not a groundbreaking innovation, but small things can make a difference”, “it looks at the human element of the process”, “it engages the staff and makes them feel they can make a difference, so they become vested in both process and outcome”.

Special Recognition

BAMA’s award for a special contribution to the aerosol industry went this year to Andy Dawson, of Hydrokem.

This is what Patrick Heskins had to say about him: “I have had the pleasure of knowing Andy as a customer, boss, colleague, mentor, and friend. He is one of the most unflappable people I have ever known, with great technical skills, a positive attitude, and a wonderful sense of humour. He has always been a fabulous supporter of BAMA, willing to share his knowledge, insight and opinion, and it is a great pleasure to be able to honour his contribution to our industry with this Special Recognition Award.”

On Thursday 12th October the delegates attending the latest BAMA Forum were hurriedly enjoying the buffet lunch that closes off the event, before saying their goodbyes.

The previous day Adrian McCretton, Chief Scientist at kdc/one Swallowfield and Chair of BAMA, had opened the event welcoming the many industry representatives present, and providing an overview of what was to come. Patrick Heskins took over to deliver an essential summary of the key initiatives and activities BAMA had been involved in during the past 12 months. From the online training videos on the basics of aerosol technology, to the UK non-methane VOC emissions targets and the Reduction Pathway designed by our industry to ensure sustainability of our sector. Patrick then related the association’s role in the review of the Aerosol Dispenser Regulation (ADR) and of the SACKI warning, widely present on personal care aerosol products. Work is underway to look at how we might update the SACKI warning for 21st century consumers to make sure they are aware of the potential risks from deliberately inhaling aerosol gas.

Next to the stage was Dai Sanders, from DCA Design International, who took us through the increasing role Artificial Intelligence (AI) is playing in shortening and facilitating the process of bringing new products to the market. At various stages, from product design to virtual consumer experience, AI is increasingly present to optimize the results and often save cost at production stage. With the caveat that human judgement and supervision will still be necessary to provide the initial data and to adjust contextual parameters.

A sharp turn to look at policymaking and at the enabling factors for the development of manufacturing in the UK. James Broughman, senior economist at MAKE UK, gave an excursus on the UK policy choices of the last decade and how they are impacting on capital investment in the manufacturing sector. Compared to the clarity of long-term strategy set by other Western economies, the uncertainty of direction and of a structured plan for the development of manufacturing in Great Britain is stifling investment and industrial growth. Labor shortage and a skills gap exacerbates the situation, as the demand for workforce has doubled in the past few years, generating higher wages in a landscape where cost savings are a priority to retain competitiveness on the market. Also, crucially, feedback from the UK industry shows that Germany is perceived as a much better environment for businesses, as the country has a strong framework of Industrial Strategy. To complement James’ presentation, Martin Traynor, Crown representative for Small Business at the Cabinet Office, explained some of the initiatives the government is taking to ease the pressure on small and medium sized businesses. First and foremost, there has been work done to open the public sector procurement contracts to SMEs, mainly through the Procurement Bill. The UK government spends £60 billion per year on goods and services, through its contracting authorities: an online tool called Contract Finder is now available on Gov.uk to help businesses identify open opportunities.

For procurement contracts under £5m in the public sector, there is now the requirement for bidding companies to show that they pay their suppliers in a timely manner, which means within either 30 or 60 days. This will indirectly help smaller companies, particularly vulnerable to the current high rates of interest for capital, to maintain a positive cashflow.

The requirement of selecting the most ‘economically advantageous’ bid has also been removed, allowing the contracting authority more flexibility to choose the best value for money rather than the lowest-priced offer.

After a short Q&A session and a coffee break that allowed people to catch up with their business contacts, the conference restarted. Brian Moore, CEO of EMR NamNews and a veteran of BAMA events, dispensed his extensive knowledge of the current trends affecting FMCG retailers. He pointed out five of them. First, Shrinkflation, or the practice of reducing the size of a product while maintaining its price. That goes hand-in-hand with Skimflation, where the quality of a product decreases because cheaper ingredients are used to keep its cost down. Both practices above have led to a Loss of Trust from consumers who have grown increasingly sceptical and have lost confidence in brands and claims. From a macro-perspective, the major supermarkets Net Profit Before Tax has gone from a standard and enviable 5%, to a generally much lower figure ranging between 0.26% for Aldi to 1.5% of Sainsbury’s, with the exception of Asda, who has been able to retain profit at 4.3%. Operating at such tight margins is challenging at best. It becomes nearly unsustainable with the Shoplifting rate gone from under 1.5% to nearly 3%, because of the squeeze on household budgets. To be able to generate the same profit for their shareholders, large retailers would need a huge increase in the amount sold, which is unlikely to happen. Looking at aerosol products on the shelves, environmental sustainability pushes the manufacturers to reduce the packaging material and size of the cans. Unfortunately, concentrated content under the current circumstances might be seen as yet another ‘rip-off trick’ by consumers, who have increasingly taken to social media to vent their frustration about shrinkflation in grocery products. A concentrate boost of energy is what the following presentation feels like, with Daniel Gibbons from Re-Solv taking the stage by storm with his dynamic delivery. The topic, abuse of aerosol products by young people, would otherwise have been all but uplifting. Likely, Daniel is used to engage classes of teenagers, in his daily job of delivery training on the dangers of solvent inhalation; principally butane and propane when aerosols are involved. The mortality rate associate with the practice is low, but surveys carried out by trained staff among children aged 10-15 revealed that in 2021 2.4% have used. In numbers, that means about 76,000 young people nationally practiced, or tried, volatile substances abuse (VSA) to get high. And unfortunately, two young girls have died of it in the past 12 months. The phenomenon is not limited to the UK: BAMA monitors the accidents occurring around the world and is aware of similar deaths in Australia, France and Sweden so far.

After questions from the attendees, Adrian invites all voting BAMA members to gather in the adjacent room for the Annual General Meeting, and dismisses the audience, reminding everyone to return later for the drink reception and Awards dinner. Thursday morning started, as has become customary, with a soft session to ease people in. This year BAMA had Mark Sproston, Head of Men’s Grooming at Quest Personal Care, capturing the audience with the story of his rise to fame as The Shavedoctor and his subsequent heart-breaking downfall. Both the successful business he had created through years of passion and work, and the credibility of his brand sunk when a joint venture in South Korea did not deliver. After a couple of difficult years, Mark received an offer of employment at Quest and The Shavedoctor brand is now back on the shelves, with a range of male shaving gels and lotions. Mark’s passion is tangible and by the time his presentation was over, all those present were well awake and ready for the interactive session next door. Arranged in teams and dressed in protective aprons, the conference delegates had to try their hand at shaving a balloon. Each person had about 1minute, before they had to hand over the cut-throat razor to the next member of their team. The result was pretty messy, luckily there were no casualties.

Back in the conference hall, a relaxed crowd welcomed Dr Bruce Adderley, Challenge Director at Innovate UK, who explained how the organization helps companies bring their project to market by finding enabling elements (such as partners, data or technology access, for instance). Once the project is defined and ready to start, there are a several forms of funding available: four Smart Grants competition per year, each totalling up to £25M, Investors Partnerships, mainly aimed at SMEs and with £80m in their current ‘Future Economy’ program, Loans at under market rates, and finally the Knowledge Transfer Partnership that connects specialized academic teams with industry. On top on this, and to address the concerns of BAMA regarding competition-law restrictions, inter-company collaborations for the purpose of innovation are welcome and actually encouraged.

Next to the stage was Charlotte Martin, director of Qualitative Research at the eponymous company. Following a number of deaths amid teenagers who inhaled aerosol propellants to get high, Charlotte undertook primary research to assess the efficacy of the existing SACKI warning (Solvent Abuse Can Kill Instantly). One-on-one interviews with selected members of the public revealed that the visual impact of the warning is extremely low, and that its wording doesn’t convey the desired message. Hardly anyone looks at the bottom half of the can, and when prompted to do so, they notice the flammable icon, mostly because of its red border, but never the SACKI warning. The extensive and in-depth research resulted in the draft of an optimal format, position and wording, to enhance visibility for the consumers and ensure they understand what danger they are warned against. The recommended format encloses a clear sentence in a red rectangular box, placed within the top half of the can. The words are chosen based on clarity and effectiveness, and they avoid unnecessary alarmism.

The Ethical Trading Initiative, in the shape of Imran Serugo-Lugo, gave an insight on the organisation’s international standard for labor rights, and flagged the potential risks associated with international trade, for example with sourcing supplies from China. The issue is not just the working conditions of the local labor, but also the human rights abuse in the global supply chain i.e. for seafarers, whose living conditions and extreme isolation cause them to be more vulnerable. When ingredients such as palm oil are concerned, manufacturers need to be aware of the unregulated work practice in the plantations, often involving women and child labor. It’s also important to keep in mind the deforestation linked to palm oil, and the need to comply with the EU Deforestation Regulation. The above are only two examples of a number of pitfalls any company filing ESG reports has to be aware of, to meet a minimum standard of ethical trade. BAMA in-house Regulatory Affairs expert, Dr Paul Jackson, closed the conference with a detailed overview of the matters that can impact on the aerosol industry, both in the UK and in the EU. The list is extensive, but the opportunity is currently there to influence policy-making through Consultations, and the UK authorities seem to be looking at simplifying the existing regulatory framework going forward.

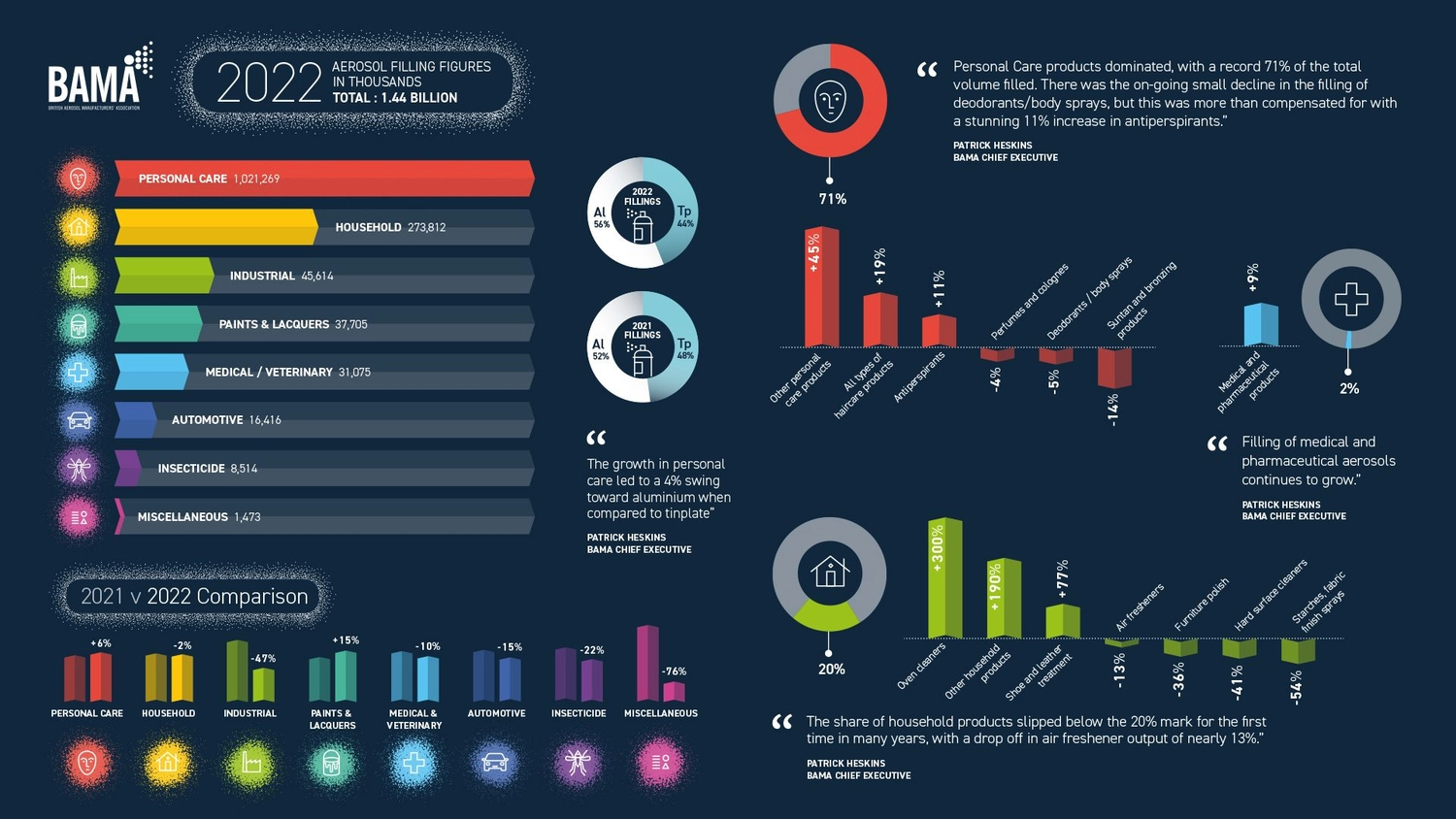

“As always, Personal Care products dominated, with a record 71% of the total volume filled. There was the on-going small decline in the filling of deodorants/body sprays, but this was more than compensated for with a stunning 11% increase in antiperspirants”.

“The haircare category saw a 19% increase as dry shampoo and root concealers grow in popularity, with a wider range of options for consumers to try, whilst we appear to have hit “peak beard” as the number of shaving products filled has stabilised”. The aerosol package appears to have been the marketers’ choice for a variety of niche products, in fact the ‘Other personal care products’ category (i.e. shower gel and mousses, insect repellent, feminine products, depilatory creams) increased by nearly 45%.

On the other hand, there was a significant decline of 14% in the number of self-tan aerosols filled last year. Patrick also points out that “the share of household products slipped below the 20% mark for the first time in many years, with a drop off in air freshener output of nearly 13% and the continuing slow decline in production of furniture polish”. The total volume for Household appears boosted: BAMA reckons that is because of the inclusion of lubricant sprays, which had previously been reported by the companies under Industrial Aerosols. Indeed, the amount by which each category has changed is very similar. “There was also a drop in the quantity of hard surface cleaners filled in 2022. Production in the category surged during COVID but as restrictions were eased so did the demand for disinfection products generally. A positive for society maybe, not so good for aerosol manufacturing. Hopefully the improvements in hygiene standards which were seen during and just after COVID, in public spaces and on public transport, will not just disappear now the worst of this infection is behind us” Patrick comments.

The numbers show that filling of medical and pharmaceutical aerosols continues to grow. This category includes medical devices, various OTC medicines and para-pharmacy products but does not include prescription medicines, such as asthma inhalers. After the initial boost in veterinary and pet care sprays led by the working-from-home need for animal company, the filling volume has probably settled back to the previous years’ average.

Paints and lacquers fillings grew in the year, but there was a small drop in the number of other Automotive products manufactured. Once we take into consideration the shift in lubricant sprays from Industrial aerosols to Household, the Industrial aerosol category shows consistency in production volume with the previous year. Focussing on some of the smallest numbers, Patrick explains that “the filling of food aerosols has never been a strong sector for the UK fillers, and what was a small volume has now shrunk to insignificance”. “Likewise, the miscellaneous category, which include novelty products such as silly string and snow sprays, has declined as the regulatory pressure on the propellant gases used for many years starts to have an impact. Many of these products still find their way on to the UK market from overseas manufacturers: whether they actually meet the UK regulatory requirements is something those placing them on the market should check very carefully”.

The growth in personal care generated a 4% swing toward aluminium when compared to tinplate. It should be noted that there are some plastic and glass aerosols filled in the UK but the numbers are very small and production is focussed on two manufacturers, so BAMA is unable to publish those figures. “We hope 2023 will allow us to get back towards the volumes we enjoyed in the late 2010’s” Patrick concludes “There are certainly a variety of challenges coming our way as an industry, but the consumer demand for products in the aerosol format doesn’t appear to be diminishing which we must use to support our business whilst we develop the next generation of products with ever-increased environmental credentials”.

The Annual Meeting from December 4-7, 2021, in Fort Lauderdale

XPAND2022, the annual meeting of the Household & Consumer Products Association (HCPA), which was held from December 4-7, 2022 in Fort Lauderdale, Florida was a great success once again. The official opening session, presided over by Steve Caldeira, President and CEO of the association, was part of the general session and provided a preview of the well-organized, exciting program that awaited the more than 400 participants. Caldeira highlighted some elements the multi-day event before presenting his annual report. Several guest speakers from the realms of economic and politics, the presentation of numerous awards -- in particular the Charles E. Allderdice Memorial Awards, which are presented each year -- were some of the highlights of this meeting.

All 7 divisions (Aerosol Products Division, Air Care Division, Antimicrobial Products Division, Cleaning Products Division, Industrial and Automotive Division, Pest Management Division and Polishes and Floor Maintenance Division) presented topics, the various sessions were very well “attended!” And Steve Caldeira’s opening speech was impressive because it made clear what the association accomplished in the past year.

Several guest speakers from the realms of economic and politics, the presentation of numerous awards -- in particular the Charles E. Allderdice Memorial Award, which is presented each year -- were some of the highlights of this meeting. The Charles E. Allderdice, Jr. Memorial Award 2022 went to Steven Christenson (Ecolab)!

HCPA Recognizes Members of the Household and Commercial Products Industry for Accomplishments in Product Innovation and Sustainability at the Fourth Annual Innovation Awards

The Household & Commercial Products Association (HCPA) announced the winners of the 2022 Innovation Awards, which honor companies within the household and commercial products industry for innovative accomplishments in five product categories: Carbon Footprint, Circular Economy, End-User Communication, Ingredients, and Technology. This time the program specifically focused on innovations that help the industry transition to an environmentally and socially sustainable economy.

“The Innovation Awards provide member companies with the opportunity to showcase the progress they are making to meet consumer demand and advance the sustainability of the industry,” said Steve Caldeira, President & CEO. “Increasingly, consumers are calling for more sustainable products, and companies have invested significant time and resources providing them. These include innovative formulations, processes, and packaging that address human health and environmental challenges. This year’s innovations protect people and the planet, create overall efficiencies in the manufacturing, processing, sale, and use of products, and help reduce greenhouse gas emissions. HCPA members are committed to developing a circular economy and educating and empowering consumers, and we are extremely proud to recognize and celebrate these companies.”

HCPA would like to congratulate the following companies for their accomplishments in developing the next generation of products and their leadership in moving the industry forward on sustainability.

Association Award

Croda

Carbon Footprint

Ecolab

Circular Economy

Eastman Chemical Company

End-User Communication

Procter & Gamble, North America Fabric Care

Ingredients

Locus Performance Ingredients

Technology

Plastipak Packaging

Nominations for the Innovation Awards were open to formulators, manufacturers, and distributors of household and commercial products. A panel of expert judges from HCPA’s Sustainability & Product Stewardship Council (SPSC) ranked the nominated products in each product category to determine the winner. The Association Award winner was determined by votes from Annual Meeting attendees based on a poster session.

The general session set a positive mood for the full virtual lecture program that extended across the next few days. All lectures as well as the committee sessions of the seven divisions were always “well-attended”. In addition to legal and technical topics, the focus of the lectures was once again on professional topics. Here is a list of the focal points of the individual lectures:

Bitte hier das Programm einbauen! Hatten wir in einer der letzten Ausgaben veröffentlicht!!!

For many years, high points of the “General Session” have been guest speeches by prominent personalities from politics, business, and culture. The keynote speaker this time was Major Garrett, Chief White House Correspondent, CBS News.

For 30 years, Major Garrett has reported from the front lines of the nation’s pressing issues, doggedly chasing and breaking news stories. He has covered Congress for two major magazines and served as White House correspondent for three television networks. He is now the Chief Washington Correspondent for CBS News.

Known for asking tough questions of all political actors regardless of party lines, Major’s extensive and award-winning print and television work is well-known and has drawn the public wrath of Presidents Obama and Trump among others. He has worked with outlets including U.S. News and World Report, The Washington Times, The Weekly Standard, and Mother Jones.

The Annual Meeting from December 6-9, 2021, in Fort Lauderdale

XPAND2021, the annual meeting of the Household & Consumer Products Association (HCPA), which was held at the beginning of last month, from December 6-9, 2021 in Fort Lauderdale, Florida was a great success once again. The official opening session, presided over by Steve Caldeira, President and CEO of the association, was part of the general session and provided a preview of the well-organized, exciting program that awaited the more than 400 participants. Caldeira highlighted some elements the multi-day event before presenting his annual report. Several guest speakers from the realms of economic and politics, the presentation of numerous awards -- in particular the Charles E. Allderdice Memorial Awards, which are presented each year -- were some of the highlights of this meeting.

All 7 divisions (Aerosol Products Division, Air Care Division, Antimicrobial Products Division, Cleaning Products Division, Industrial and Automotive Division, Pest Management Division and Polishes and Floor Maintenance Division) presented topics, the various sessions were very well “attended!” And Steve Caldeira’s opening speech was impressive because it made clear what the association accomplished in the past year, despite the Corona crisis. In an interview with Steve Caldeira, he explains the association's successes in the past year for us. We will publish the interview in the next issue of AEROSOL EUROPE.

PRODUCT DIVISION CHAIRS - ADVISORS TO THE BOARD

Aerosol Products Division

Nick Ferring, PLZ Aeroscience

Air Care Products Division

Eileen Hedrick, Symrise NA

Antimicrobial Products Division

Teresa Moore, The Procter & Gamble Company

Cleaning Products Division

Mauricio Amaya, Synergy Life Science, Inc.

Floor Care Products Division

Carmine Savaglio, SC Johnson

Industrial & Automotive Products Division

Michele Rudnick, CRC Industries

Pest Management Products Division

Lisa Dreilinger, RB

Several guest speakers from the realms of economic and politics, the presentation of numerous awards -- in particular the Charles E. Allderdice Memorial Award, which is presented each year -- were some of the highlights of this meeting. The Charles E. Allderdice, Jr. Memorial Award 2020 went to Joe Yost!

During the Annual Meeting HCPA also announced the winners of the 2021 Innovation Awards, which honor companies within the household and commercial products industry for accomplishments in innovation and sustainability in five product categories: Ingredients, Sustainability, Consumer Communication, Technology, and Game Changer.

HCPA would like to congratulate the following companies for their accomplishments in developing the next generation of products that encourages innovation and moves the industry forward.

Ingredients

Locus Performance Ingredients

Amphi M Sophorolipid

Sustainability

Selig Group

Circumvent and Airfoil for Bleach Products

Technology

Locus Performance Ingredients

Novel Biosurfactant Production Technology

Game Changer

Selig Group

Circumvent and Airfoil for Bleach Products

Nominations for the Innovation Awards were open to formulators, manufacturers, and distributors of household and commercial products. A panel of expert judges ranked the nominated products in each product category to determine the winner.

The general session set a positive mood for the full virtual lecture program that extended across the next few days. All lectures as well as the committee sessions of the seven divisions were always “well-attended”. In addition to legal and technical topics, the focus of the lectures was once again on professional topics. Here is a list of the focal points of the individual lectures:

For many years, high points of the “General Session” have been guest speeches by prominent personalities from politics, business, and culture. The keynote speaker this time was Travis Mills. On April 10, 2012, United States Army Staff Sergeant Travis Mills of the 82nd Airborne was critically injured on his third tour of duty in Afghanistan by an IED (improvised explosive device). As a result of the blast, Travis lost portions of both arms and legs. He is one of only five quadruple amputees from the wars in Iraq and Afghanistan. Enduring a grueling rehabilitation program, Travis committed himself not only to recovery, but to fatherhood and to giving back to the veteran community any way he could. Travis’s story has been featured extensively on local and national news, including The Ellen DeGeneres Show, NBC, CBS, Fox News, The O’Reilly Factor, CNN, to mention a few.

Aztec Aerosols is a professional and trusted aerosol-filling manufacturer with a broad range of print and fill options. With decades of experience in aerosol contract filling, our modern automated filling lines and blending facilities allows us to provide you with an extensive range of cost-effective, quality products in a wide variety of sizes, formats and quantities.

Our history in aerosol contract filling dating back to 1964, Aztec Aerosols as we know it was founded in 1995. Aztec Aerosols began production in Croydon before they expanded their production facilities and moved to Crewe in 1999.

Over the last 27 years, Aztec Aerosols has combined technical knowledge with innovative design to provide reliable products and added value to their client’s brands. Aztec Aerosols has grown and developed from a small aerosol manufacturer in the North West to market-leaders in the UK.

The team at Aztec Aerosols has vast experience in aerosol contract filling, allowing us to provide an extensive range of cost-effective, quality products in a wide variety of sizes, formats and quantities. Supporting us is a team of technical staff who offer confidential advice on product formulation and legal requirements.

Our ‘Total Product Development’ policy begins from our initial consultation with you. We will work with you to get a full understanding of your business and aerosol requirements before moving to a specification and design stage. Our Research & Development team will research and develop your formulation, helping you to create a completely bespoke product.

In 2017, Aztec Aerosols was acquired by Instarmac Holdings. Instarmac Holdings are an award-winning, Sunday Times Top 100 business, who operates out of state-of-the-art manufacturing facilities in central England. Instarmac produce and supply market-leading products to the highway maintenance, tiling, flooring, and landscaping markets all around the world.

Aztec Aerosols are now gaining the support and investment Instarmac Holdings can offer and significant investment has already been made to improve efficiencies, process improvement and ultimately, customer experience.

Contract Filling & Private Labeling

Aztec Aerosols is a contract aerosol manufacturer that provides an outstanding service, tailored to the customers’ individual requirements.

Our onsite laboratory and blending facilities provide customers the ability to create their own formulation and contract blends which we can then fill to their requirements.

For those customers who have their own contract formulation or blend, Aztec offers a discrete filling service helping bring these branded aerosols to market quickly.

Need further support? Our Technical Research & Development team has over 3000 tried and tested formulations for use in various industry sectors, we are sure to have a private label aerosol for you.

At Aztec we have a broad range of print and fill options, if you use or supply aerosols we would be delighted to discuss your needs and put forward our proposals.

Aztec Aerosols onsite laboratory and blending facilities are run by a specialist team of chemists and technicians who have extensive knowledge and experience across multiple industry sectors.

Our team works with customers to help create their own formulations and new contract blends, which we then fill to their requirements. Aztec also undertakes compatibility testing to ensure the aerosols are suitable for their intended purpose.

Research & development is at the forefront of our operations and is crucial when supporting our customers. Our team can advise on all aspects of product development, ensuring that your products meet all of the industrial health and safety standards and guidelines.

Product Research & Development

At Aztec Aerosols we have a professional team of chemists and technicians who have extensive knowledge and experience across multiple industry sectors. Research & development is at the forefront of our operations and is crucial when supporting our customers.

Our team can advise on all aspects of product development and with over 3000 specialist formulations can offer the best product within the customer’s specified parameters.

In addition, with our technical team’s experience and expertise we ensure that products meet all of the industrial health and safety standards and guidelines. This includes the supply of up to date, comprehensive legislative advice and Safety Data Sheets in various languages.

Our many years of product development and proven formulations ensures flexibility and maximum efficiency when tending to all of our customer’s requirements.

Production Methods & Capabilities

Aztec Aerosols is a contract filler of aerosols based in the UK. Our aerosols are produced at our state of the art production facilities in Crewe. We have the capacity to fill up to 40 million cans a year, all of which are tailored to the customers’ individual requirements and filled on 3 modern fully automated production lines.

We carry over 3000 formulations in house for use in various industry sectors, we can blend in house or discreetly utilize customers own formulations and blends.

If you would like more information on how Aztec Aerosols could help your business, get in touch – we would be happy to discuss your requirements.

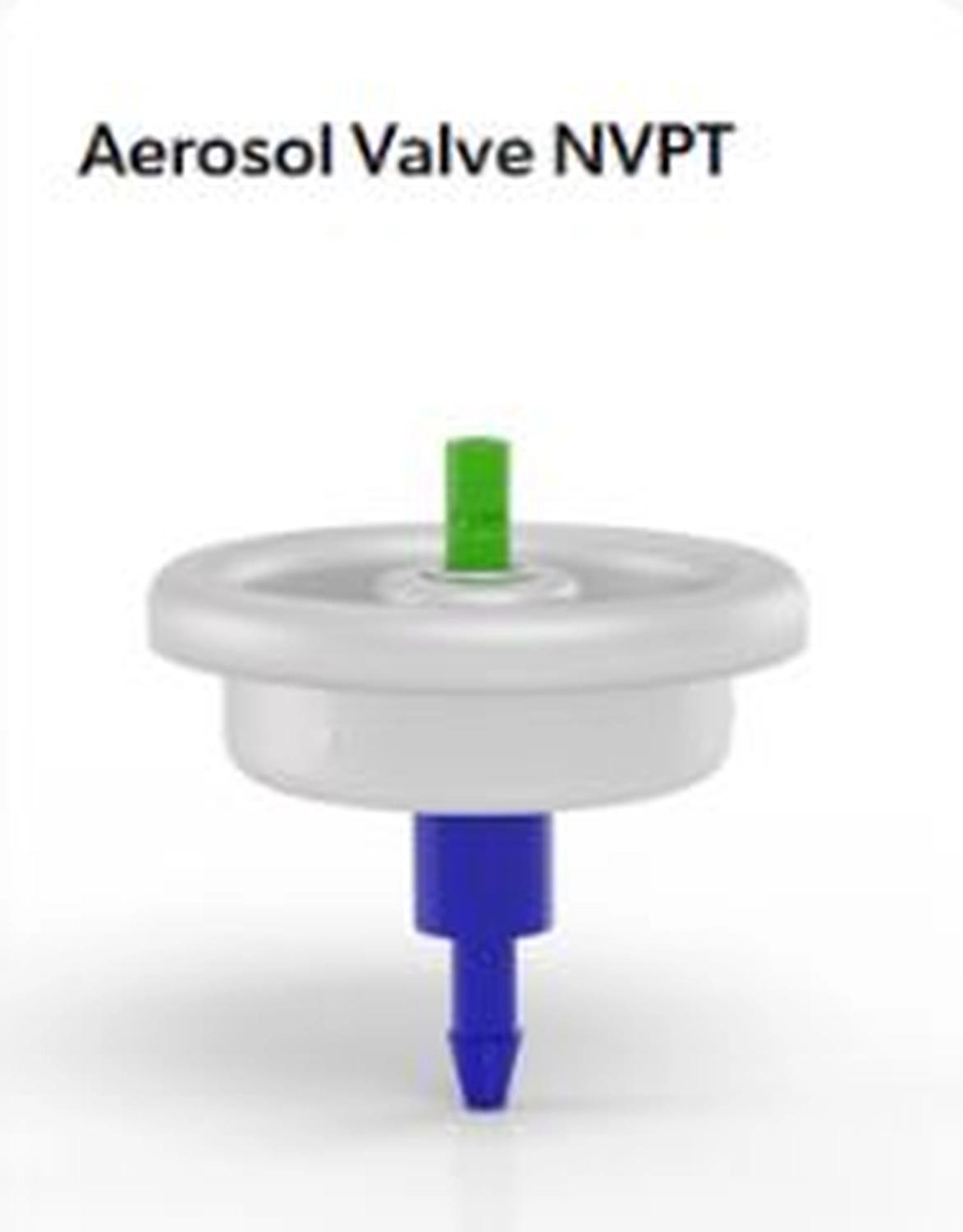

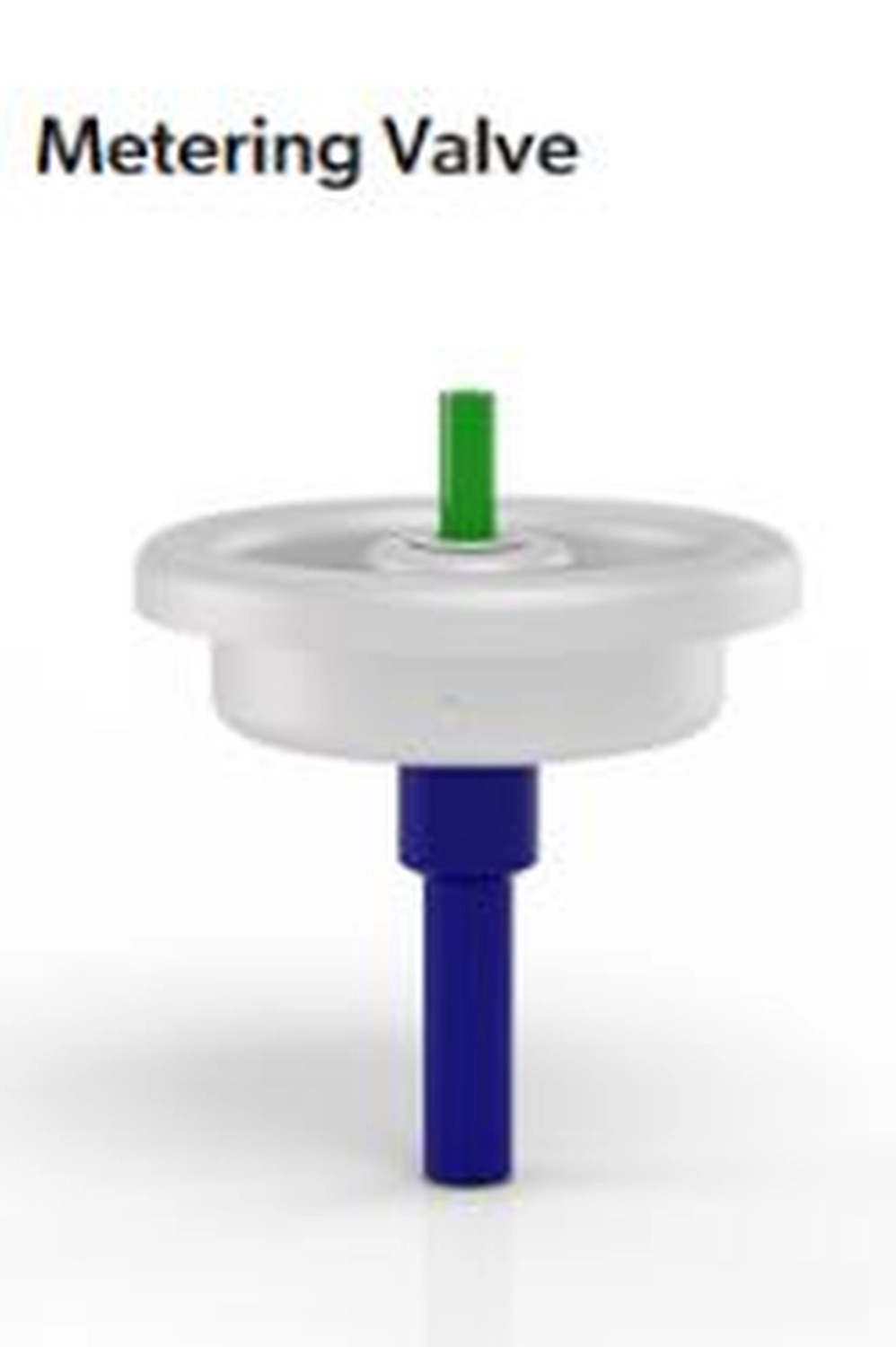

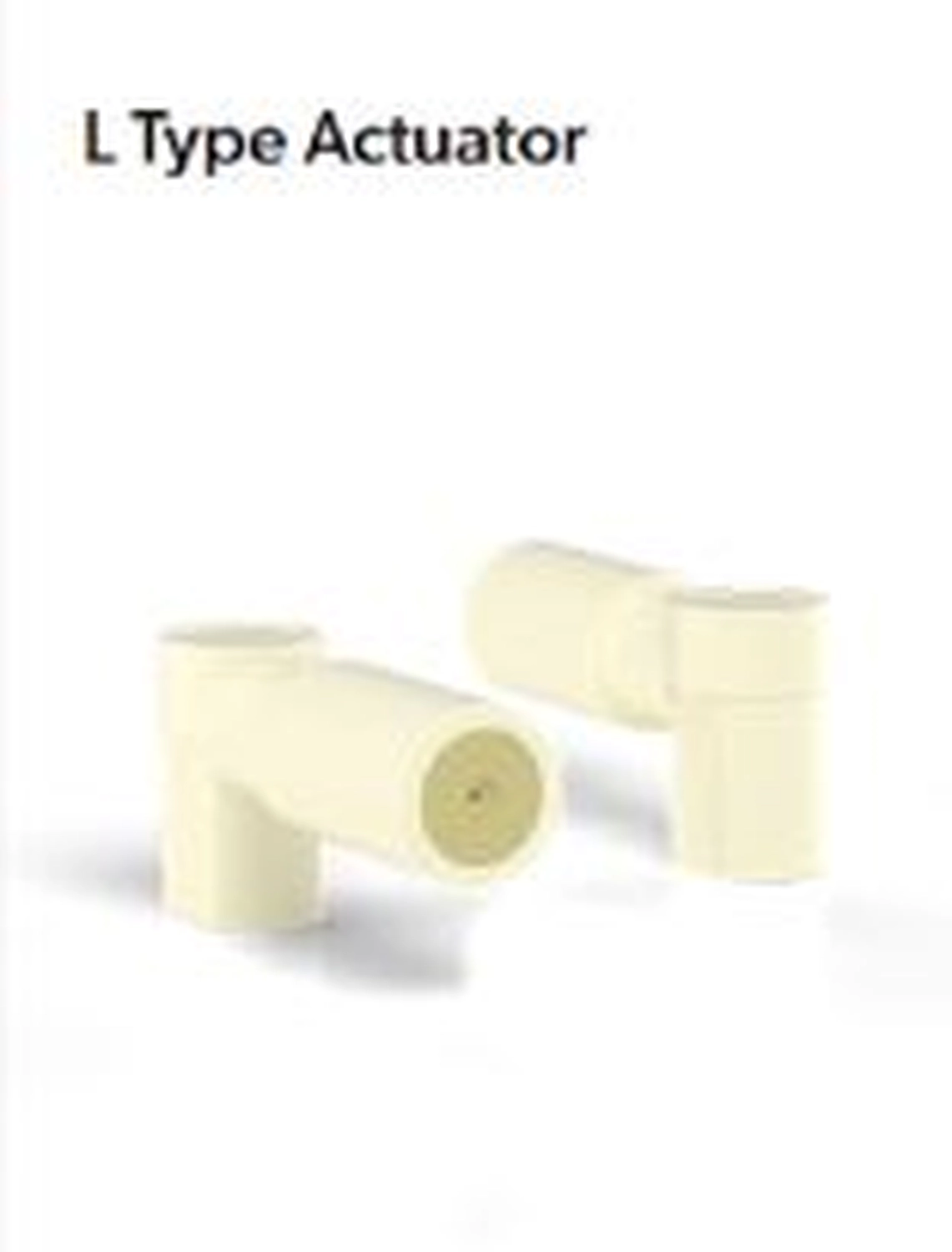

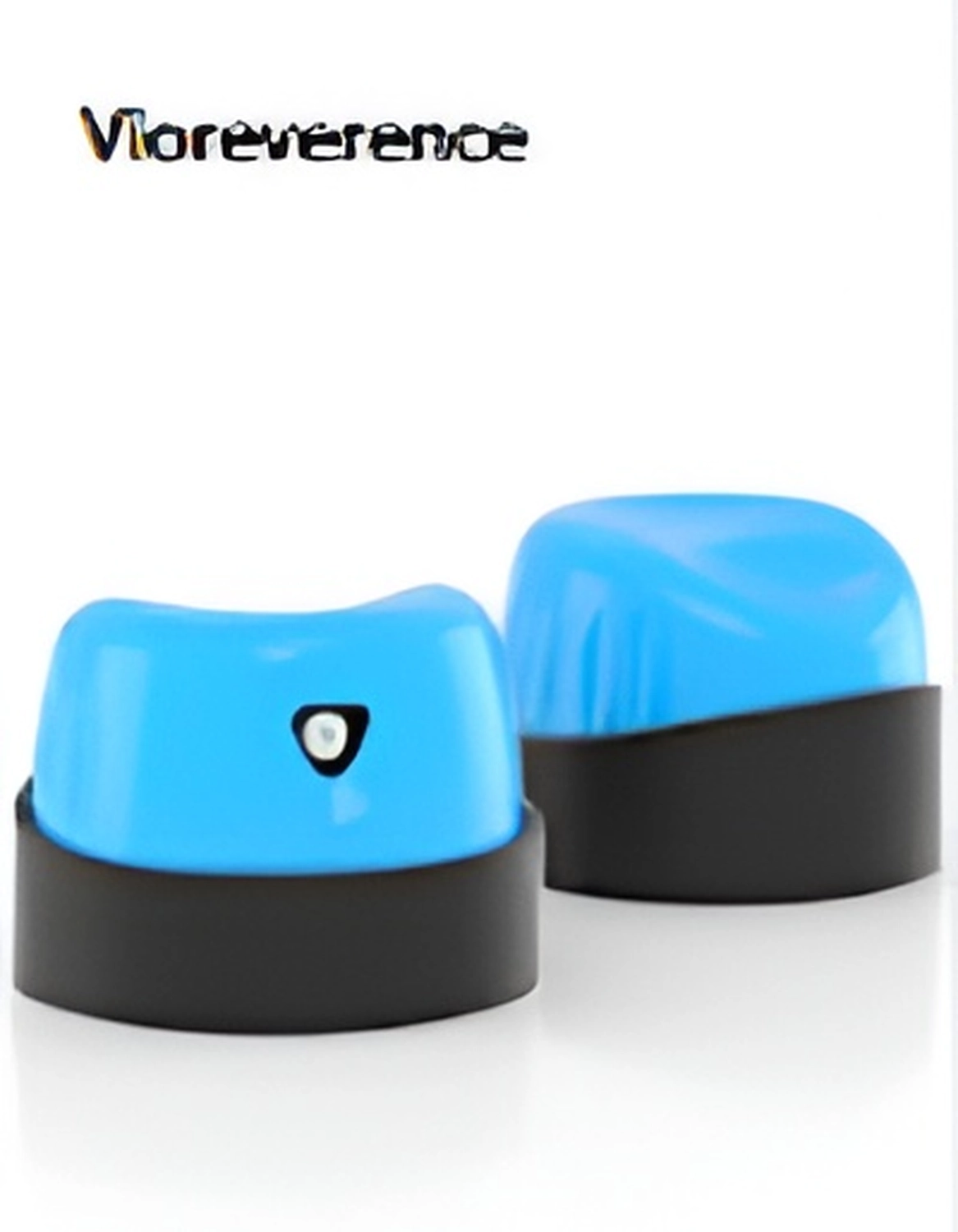

An aerosol is made up of several basic components:

An aerosol can

The product

The propellant

A valve

An actuator

A dust cap

Here at Aztec Aerosols, these all have to be assembled, and this is achieved using automatic filling machinery.

Our process starts with an empty container which is either made from tinplate or aluminium.

The empty containers travel along the production line and the bespoke product, in the form of a liquid, is added to the can. This contains all of the active ingredients.

The volume of liquid is very carefully controlled to ensure that it conforms to Weights & Measures legislation.

Our state of the art equipment then fits the Aerosol valve to the can.

From there, the cans continue along the production line and the machinery injects the propellant, under pressure, through the valve. The aerosol is now in a pressurized state due to the addition of the propellant.

Construction Aerosols

Trades such as carpentry, painting and decorating, electrical, plumbing, tiling and flooring all fall within the construction sector. Each trade might be working in domestic, commercial of industrial environments and therefore their needs can vary significantly.

There is a high demand for very specific aerosols, such as degreaser sprays, line marking paint and detection sprays, as well as general, multi-purpose maintenance sprays.

Aztec Aerosols has a long and successful history of providing the construction sector with market-leading and trusted aerosols, ideally suited for the intricate needs of the construction sector.

Automotive Aerosols

Automotive aerosols are sold for both mass-market and professional use and because of this, the types of products needed to meet demand are somewhat varied.

At Aztec we have decades of experience manufacturing cleaning, maintenance and paint aerosols for the automotive industry. Some of the cleaning aerosols we have experience with include engine cleaners, tyre cleaners, brake cleaners, dashboard and console cleaners as well as carpet and upholstery cleaning products. Car maintenance products include de-icers, anti-fog aerosols and lubricating oils, greases and silicones.

The most popular type of automotive aerosol is car paint. Aerosol spray paint is the ideal solution for colour matching chips and damaged bodywork and completely new paint jobs.

Aztec Aerosols have been working closely alongside leading brands within the automotive industry for many years. Our expertise in this field is driven by a desire to find solutions for a range of precise industry needs.

Take a look at the links below for information on the specific areas of the automotive sector we can assist with.

Household Aerosols & Manufacturing

Household aerosol products represents 21% of the current aerosol production in Europe. Household aerosols are dedicated to home cleaning and maintenance. Products include paints, fabric protector, cooking sprays, cleaning products and room deodorizers or air freshening sprays. They are affordable and widely available.

Household aerosols are clean and sanitary. They can be applied without contact, while protecting users from germs.

Aztec Aerosols have been providing households, and the professional cleaning industry with cleaning aerosols for many years. Their clean production facilities are ideal for manufacturing these type of aerosol sprays.

Agricultural Aerosols

Aerosols offer targeted application, consistent coverage, and portable convenience—making them an essential tool for modern agriculture.

Backed by our state-of-the-art filling lines, custom-formulation expertise and industry-leading lead times, we partner with agricultural businesses to deliver reliable, high-performance aerosols tailored to your exact specifications, as well as industry standards.

Fly and parasite repellents deter nuisance insects like flies, lice, and ticks, which can otherwise cause irritation, reduce feed intake, and spread disease. Effective insect control reduces animal stress and improves productivity—especially important in warmer months or enclosed housing systems.

ILERSPRAY is a company specialized in the manufacturing of aerosols and chemical products for sectors such as cosmetics, automotive, home, and industry. Located in Lleida, less than two hours from the Port of Barcelona, the modern facilities and production lines allow us to respond quickly and accurately to market demands.

ILERSPRAY was founded in 2014, born from its experience in the chemical sector and a natural market need. With a deep knowledge of the aerosol and automotive markets, ILERSPRAY focused on manufacturing, handling, and packaging chemical products for the automotive, home, and industrial sectors, as well as offering third-party packaging services.

Packaging

ILERSPRAY is capable of filling both aluminum and tinplate cans from the world’s leading suppliers. All cans, ranging from 45 to 65 mm in diameter, comply with FEA standards, whether they are lithographed or labeled. ILERSPRAY also offers product labeling services for the finished product.

Production Lines

There are three aerosol packaging lines, one liquid packaging line, and one gel air freshener packaging line.

Mixing Area

ILERSPRAY has two 18,000L tanks and one 35,000L tank for the production of antifreeze and/or windshield washer fluid. In the aerosol mixing area, there are three 1,000L mixers and one 250L mixer. All of them are equipped with numerical controllers to prevent errors.

MEPLAST founded in 1991 at Istanbul, Turkey as an injection moulding contract manufacturing company providing service for multiple industries based on the expertise of the founders in a modest facility. Meplast moved to its current location in 1999.

In 2002, Meplast launched its first product line of simple aerosol caps and closures for several diameters under the trademark name of VIOCAP. Today, VIOCAP is one of the most influential aerosol dispensing solution partners in Europe, exporting its goods to more than 30 countries globally, and supplying a variety of industries.